Website:

Jefa

Website:

Jefa

Catalog excerpts

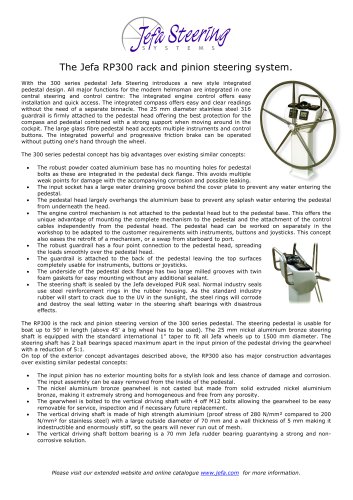

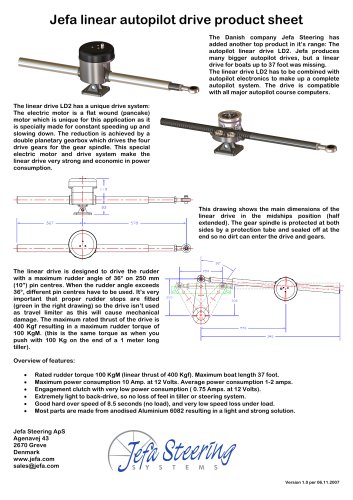

Jefa 150 KgM direct autopilot drive type DD-1 The Jefa direct drive type I is an extremely strong and compact autopilot drive and much more efficient than existing hydraulic and electro-mechanical autopilot drive units. It's much stronger than a human being (the max. output torque of 150 KgM is equivalent to 150 Kg force on the end of a 1 meter steering tiller) and is build for 24 hours per day continuous operation with a total weight of only 12 Kgs. The combination of the flat wound (pancake) electric motor with the ultra efficient planetary and spur gearbox results in an extremely efficient drive unit to keep the battery charging time to the minimum. The drive can be used on boats from 30 to 45 foot l.o.a. (or up to 150 Kgm rudder torque) equipped with a mechanical steering system that can be back driven. Due to the electro mechanical clutch, the direct drive cab be back driven with the force of a finger tip leaving the mechanical steering as sensitive as without drive unit. The Jefa 150 KgM direct drive type 1 is very compact with a length of 345 mm, a width of 164 mm and a height of 192 mm. As space is always a problem on sailing yachts, the direct drive unit can be mounted as close as 250 mm from the rudderstock even upside down. rudder stock stop plate draglink output lever direct drive Mounting variations: The direct drive drives the rudder via a draglink and the existing tiller arm or quadrant or via an independent tiller arm. The drive can be mounted behind or next to the rudderstock, driving the rudder directly or in front of the pedestal driving the rudder via the pedestal. Electrical connections: autopilot control head fluxgate compas autopilot junction box rudder feedback unit drive unit This illustration shows the minimal components for a working autopilot configuration. Jefa autopilot drives work together with all mayor autopilot electronics. The connection of the Jefa autopilot drive to the autopilot junction box is quite simple. The two 0.75 mm² red and black wires have to be connected to the plus and minus of the autopilot clutch line. This will make sure that when the autopilot user engages the autopilot on the control screen, the clutch will engage and allow the autopilot motor to drive the steering system. The two 2 mm² red and black wires have to be connected to the autopilot drive output connection. Jefa direct drive DD1 brochure version 1.2 page 1 of 3. For more info and installation information visit www.jefa.com

Open the catalog to page 1

The construction: This assembly drawing shows a cross section of the direct drive type I. The drive can be separated in 5 main parts: The electric motor, the two step spur gearbox, the planetary gearbox, the electro-magnetic clutch and the final spur reduction gearbox. The Jefa direct drive has multiple advantages over existing integrated drive units. These advantages will be explained per section of the drive: Electric Motor: The flat wound electric motor (pancake motor) used in the Jefa drive units is carefully selected for this application. Pancake motors have multiple advantages over...

Open the catalog to page 2

Mechanical installation: The direct drive uses “wide angle geometry”. The result of this is 128° travel of the output lever and 72° travel of the tiller lever. To achieve an equal travel of the drive in port and starboard, the centre point of the output lever needs an offset to the rudderstock centre. The offset depends on the used lever centres. Following table shows the correct offset distances: offset tiller center output center Operating centres in mm valid for 72° (2x36°) rudder travel. Output centre Offset distance Tiller centre Compatibility in 12 Volts: Following table shows the...

Open the catalog to page 3All Jefa catalogs and brochures

-

LD100

7 Pages

-

RP 200

2 Pages

-

RP300

2 Pages

-

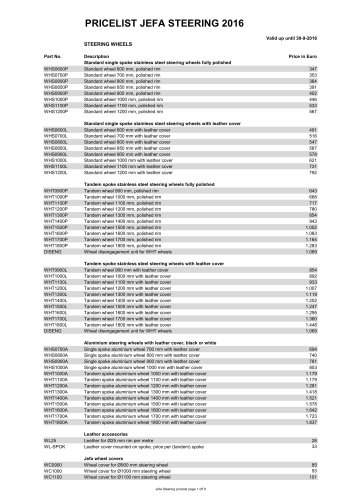

PRICELIST JEFA STEERING 2016

8 Pages

-

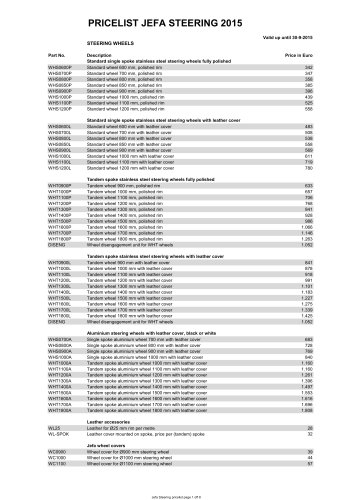

pricelist-steering-2015

8 Pages