Catalog excerpts

WARNING Care of the ENVIRONMENT is the responsibility of all individuals and not that of someone else. If you love fishing, boating, or make your living from either, then please take good care of the sea and it's environment. HYDRAULIC OIL is NOT ENVIRONMENTALLY FRIENDLY and care should be exercised to prevent oil used during the bleeding process from running overboard, or into the bilge where it will be pumped into the sea. It only takes a little time and patience to protect the sea from further pollution. Please dispose of all waste oil, rags, plastic bags and other materials, thoughtfully and in a responsible manner. WE WISH YOU HAPPY BOATING! REVISION 2005-1 (21/03/2005) ADMIRAL HD SERIES Hydraulic Boat Steering INSTALLATION INSTRUCTIONS & OWNER'S MANUAL MANUFAC TURED BY HY-DRIVE ENGINEERING PTY LTD ABN 14 007 660 808 59 WINGFIELD ROAD, W INGFIELD, SOUTH AUSTRALIA 5013 Telephone: +61 8 8243 1633 / Fax: +61 8 8445 7938 www.hydrive.com.au Email: sales@hydrive.com.au

Open the catalog to page 1

Admiral HD Series - Installation Manual - Page 42 Admiral HD Series - Installation Manual - Page 3 Warranty Statement SAFETY INFORMATION HyDrive HD Series steering units are warranted by the manufacturer against defect in workmanship and materials for 24 months from date of sale. FACTORY WARRANTY Units suspected of warranty problems should be returned to the factory, freight paid together with your name, address and description of the problem. No inbound freight charges will be accepted. Warranty is limited only to repair or replacement of any component found to be faulty and such repair or...

Open the catalog to page 3

Admiral HD Series - Installation Manual - Page 4 VERY IMPORTANT PO INTS TO NOTE Before proceeding please read the following sections relating to items that are of major importance to the correct installation and selection of components. DO NOT US E BRAKE FLUID IN THIS S YSTEM - IT WILL DAMAGE S EALS AND OTHER COMPONENTS. USE ONLY HYDRIVE ULTRA-15 HYDRAULIC OIL. WARNING: Use of alternative hydraulic fluids may result in premature seal wear and possibly cause damage to your system. S uch damage is not covered under your conditions of warranty. DO NOT USE ALTERNATIVE HYDRAULIC FLUID UN LESS...

Open the catalog to page 4

Admiral HD Series - Installation Manual - Page 40 TROUBLE SHOOTING GUIDE LUMPY OR NOTCHY STEERING The most common cause of this complaint is air in the system. C heck all joints and re-bleed the system. Another cause is the use of the wrong grade of tubing. High pressure flexible hoses can allow expansion, and result in notchy steering. It is dangerous - take it off the boat IMMEDIATELY, and get the right tubing. OIL OVERFLOWING Do not overfill the pump unit, but leave the oil level about 12mm from the bottom of the thread in the filler hole on the pump (about 1/2" from the bottom of the...

Open the catalog to page 5

Admiral HD Series - Installation Manual - Page 6 RECOM M ENDED TILLER LENGTHS vary from model to model and are adjustable depending on the rudder angle required. Recommended Tiller Lengths for 70 Degree Inclusive Cylinder Type Inches Mm HD150-9 8.015 203.581 HD175-10 8.906 226.212 HD150-12 10.687 271.450 (HD175-12 & HD200-12) 10.687 271.450 HD250-12 10.687 271.450 HD250-15 13.359 339.319 HD400-12 10.687 271.450 POINTS TO WATCH PRIOR TO INSTALLATION All hydraulic equipment requires a good degree of workmanship for its installation, and this is also true of steering gear, if future...

Open the catalog to page 6

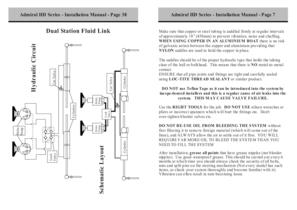

Admiral HD Series - Installation Manual - Page 38 Cylinder Make sure that copper or steel tubing is saddled firmly at regular intervals of approximately 18” (450mm) to prevent vibration, noise and chaffing. WHEN USING COPPER IN AN ALUM INIUM BOAT there is no risk of galvanic action between the copper and aluminium providing that NYLON saddles are used to hold the copper in place. Cylinder Schematic Layout Helm P ump Lock Valve Helm Pump The saddles should be of the proper hydraulic type that holds the tubing clear of the hull or bulkhead. This means that there is NO metal-to- metal contact....

Open the catalog to page 7

Admiral HD Series - Installation Manual - Page 37 USING COPPER TUBING Helm Pump 5) P lace the flare in position against the fitting seat and slide up the nut and screw it on squarely so as not to cross the thread. Tighten it by hand only until it becomes firm. 6) YOU MUST USE TWO SPANNERS - one on the fitting (T-piece, elbow or straight fitting) and the other on the nut. Use the two spanners against each other to take the load - not the fitting. Use only 8" or 200mm long spanners - NO LARGER. In this way you can apply much greater force without damaging the fitting itself. Cat Va lve...

Open the catalog to page 8

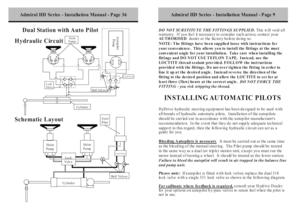

Admiral HD Series - Installation Manual - Page 36 Dual Station with Auto Pilot Autopilot Pump Hydraulic Circuit Helm Pumps Lock Valve Lock Valve Admiral HD Series - Installation Manual - Page 9 DO NOT SUBSTITUTE THE FITTINGS SUPPLIED. This will void all warranty. If you feel it necessary to consider such action, contact your AUTHORISED dealer or the factory before doing so. NOTE: The fittings have been supplied loose with instructions for your convenience. This allows you to install the fittings at the most convenient angle for your installation. Take care when installing the fittings and...

Open the catalog to page 9

Admiral HD Series - Installation Manual - Page 10 STANDARD AUTOPILOT STANDA RD AUTOPILOT INSTA LLATION DIA GRAM INSTALLATION DIAGRAM Admiral HD Series - Installation Manual - Page 35 Dual Station Helm Pumps Autopilot Pu mp unit. Either bi- directional OR Solonoid type unit. Ball Valves 318 Dual Lock Valve used when pilot does not have own (Do valve Lock valve lock not use if one Manual helm with vented filler cap. Balance line Hydraulic Circuit installed in p ilot pu mp already) TOptional 331 lock valve if autopilot has internally fitted lock valve. Lock Valve To Slave cylinder(s) Cylinder...

Open the catalog to page 10

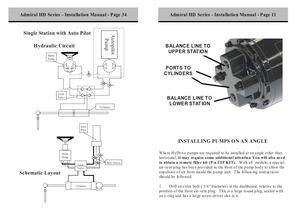

Admiral HD Series - Installation Manual - Page 34 Hydraulic Circuit Helm Pump Autopilot Pump Single Station with Auto Pilot Admiral HD Series - Installation Manual - Page 11 BALANCE LINE TO UPPER STAT ION PORTS TO CYLINDERS Lock Valve Cylinder BALANCE LINE TO LOWER STAT ION Auto Pilot INSTALLING PUMPS ON AN ANGLE Helm Pump Lock Valve Schematic Layout Cylinder Ba ll Va lves Where HyDrive pumps are required to be installed at an angle other than horizontal, it may require some additional attention You will also need to obtain a remote filler kit (P/n CIP KIT). W ith all models, a special...

Open the catalog to page 11All Hydrive catalogs and brochures

-

POWER ASSISTED STEERING

12 Pages

-

12 VOLT DC POWER STEERING

2 Pages

-

HD Series

9 Pages

-

Outboards & Sterndrives

10 Pages

-

E SERIES ELECTRONIC STEERING

2 Pages