Catalog excerpts

Miniature and Subminiature Solenoid Valves Gems specializes in made-to-order fluidic systems, and a major segment of that activity includes the integration of miniature solenoid valves and manifold assemblies. Our miniature and subminiature solenoid valves are utilized in solutions that serve industries ranging from medical and biotech to automotive and industrial equipment. Gems solenoid valves are designed to your specifications for each unique application. Each series offers a broad range of construction/performance options to build an endless array of configurations—too many to list in this catalog. From custom coils and manifolds to exotic materials and flow characteristics, there is very little that we cannot accomplish. Whether pneumatic or liquid, cryogenic or high temperature, vacuum or high-pressure, we partner with you to identify, create, and produce the best possible fluidic solution. If at any time, you have a question or simply want to give us your requirements and have Gems Sensor and Controls design your valve or system, please contact us by phone at 800-378-1600 or email us at info@gemssensors.com. Get Help Quick An application data sheet (ADS), located on page J-40, will help you select performance criteria and options. Fax it directly to a Gems Valve Engineer at 860-747-4244 or configure your valve online for RFQ at www.gemssensors.com. General Purpose Valves A broad range of 2- and 3-way solenoid valves in both miniature and subminiature sizes. A wide selection of configuration options allows easy customization to match specific application requirements. Isolation Valves Isolation diaphragms protect media and moving parts alike. Ideal for high-purity and aggressive media applications. Page Start Cryogenic Valves These valves provide reliable service to media temperatures as low as -320°F (-196°C). Ideal for liquid Nitrogen and Carbon Dioxide use. Visit www.GemsSensors.com for most current information.

Open the catalog to page 1

4 Steps to Valve Selection The steps described in this section will help you identify the performance criteria needed to meet your application requirements and select the right valve. Begin by calculating the valve flow coefficient (CV) using: operating pressure differential; flow rate for your application; Specific Gravity; and in some circumstances, temperature. If you already know your CV please go directly to Step 2. CV combines the effects of all flow restrictions in the valve into a single number. CV represents the quantity of water, at 68°F and in gallons per minute (GPM) that will...

Open the catalog to page 2

Sensors & Controls Step 2 - Valve Function Identify how your valve will function in your application. Pick from the choices below. An important note regarding Cv and valve function: The Cv calculated will apply to either the Body Orifice or the Stop Orifice depending on For example, the Stop Orifice for a 3-way normally closed valve, when de-energized, is the exhaust port. In other words, Cv is calculated using the specific Inlet Pressure (P1) and Outlet Pressure (P2) for the flow paths described below. Blocked Flow Free Flow DE-ENERGIZED ENERGIZED DE-ENERGIZED ENERGIZED 2-WAY NORMALLY...

Open the catalog to page 3

INTRODUCTION Step 3 – Identify Your Valve Series Select possible valve series candidate using the overview charts below. Begin by choosing the category for your application: If you would like assistance with your selection, want to modify a valve, or simply want a sounding board please contact a Gems™ valve engineer at 800-378-1600 or info@gemssensors.com. • General Purpose • Isolation • Cryogenic Using the charts, select maximum operating pressure differential (MOPD), the CV, function, and additional specifications needed for your application to select possible valve series. The detailed...

Open the catalog to page 4

M Series – Subminiature MOPD: 100 PSI CV Range: 0.018 to 0.070 As Low As 0.5 Watts The M Series implements efficient power conservation in a solenoid valve that is specifically designed for sub-miniature two- and three-way pneumatic and select liquid applications. Field proven to exceed performance requirements in battery-powered applications, the M Series can be designed for extreme low wattage conditions. With a compact size, consistent high-speed response time, and reliable operation over 200 million cycles, the M Series delivers extended performance and precision flow control in a small...

Open the catalog to page 5

GENERAL PURPOSE Part Prefix Table Power Rating 0.5 Watt 1 Watt 2 Watts MOPD (psig) 2 Valve Type 20 = 2-Way normally closed 22 = 2-Way normally open 30 = 3-Way normally closed (free vent) 31 = 3-Way normally closed (line connection) 32 = 3-Way normally open 33 = 3-Way multi-purpose 34 = 3-Way directional control 3 Orifice Size 2 = 0.031˝ 5 = 0.052˝ 7 Stop Port Configuration 0 = No barb (Standard for 2-way NC & 3-way free vent) 1 = 1/16˝ barb (.031˝ orifice only) 2 = 5/64˝ or 3/32˝ barb 3 = 1/8˝ barb 8 Coil Construction U = P.C. board solderable (2-pin) P = P.C. board mount (4-pin) Q = Quick...

Open the catalog to page 6

E & EH Series – Subminiature Gas MOPD: 175 PSI CV Range: 0.018 to 0.070 0.65 Watts or 2 Watts A 2- or 3-way sub-miniature solenoid valve that delivers faster response times— and higher flow rates, the E & EH Series is specifically engineered for air and dry gas applications. A nickel-plated body and coil housing construction produces a highly durable, corrosion resistant valve. With a wattage range of 0.65–2 the E & EH Series provides versatility for power conserving, high pressure, and high flow applications. Typical Applications • Medical and Respiratory Healthcare • Printing Machinery...

Open the catalog to page 7

GENERAL PURPOSE Power Rating MOPD (psig) 2 Coil Construction (blank) = Tape-wrapped, Class-B, with lead-wires (12˝ long)* W__ = Lead-wires, non-standard length (specify in inches) 1 = Encapsulated coil 5 = Encapsulated coil with 0.110 spade terminals 10 = Rectified coil for AC voltage (2 watt only) 3 Body Material (blank) = Nickel-plated brass* 4 Plunger Seal Material (blank) = Nitrile* V = Viton® E = EPR MQ = Silicone 5 O-Ring Material (blank) = Nitrile* VO = Viton® EO = EPR MQO = Silicone 6 Body Port Configuration (blank) = #10-32 straight thread ports* BM = M5 x 0.8 ports MM = Manifold...

Open the catalog to page 8All Gems Sensors catalogs and brochures

-

D-Cryo Series Solenoid Valve

2 Pages

-

B-Cryo Series Solenoid Valve

2 Pages

-

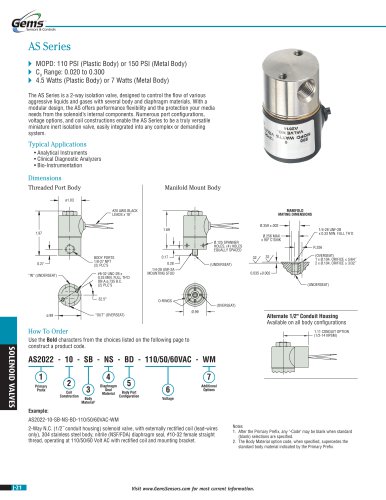

AS Series Solenoid Valve

2 Pages

-

BS Series Solenoid Valve

2 Pages

-

KM/KL Series Solenoid Valve

4 Pages

-

KV/KW Series Solenoid Valve

2 Pages

-

PM/PL Series

2 Pages

-

Gems Master Catalog Product

406 Pages

-

3600 Series

4 Pages

-

3800 Series

2 Pages

-

3500 Series

4 Pages

-

F Series

4 Pages

-

Appendix and Glossary

13 Pages

-

Pressure Transducers

67 Pages

-

Pressure Switches

30 Pages

-

Flow Switches

26 Pages

-

Warrick Conductivity Sensors

29 Pages

-

Level Sensors Continuous

33 Pages

-

Level Indicators Visual

27 Pages

-

Level Switches Multi-Point

26 Pages

-

Warrick_Conductivity_Sensors

29 Pages

-

Level_Sensors_Continuous-

33 Pages

-

Level_Indicators_Visual

27 Pages

-

Level Switches Single Point

43 Pages

-

Level_Switches_Mult-Point

26 Pages

-

Flow Sensors

13 Pages

-

Electronic_Products-

13 Pages

-

J-Valves_05-16-2011opt

40 Pages

-

Proximity_Switches-

5 Pages

-

Flow_Switches

24 Pages

-

Pressure_Switches

28 Pages

-

Pressure_Transducers-5-16-2011

44 Pages

-

Gems_ProdOverview_2008_Opt_Print

12 Pages

-

SemiconBroch

8 Pages

-

FS-380P Series

2 Pages