Catalog excerpts

Gems Transducers Deliver Top Performance and Value Under Pressure! ► Excellent Repeatability, Reliability ► Sensing Ranges from Vacuum to 10,000 psi (-1 to 689 bar) ► Broad Range of Sensing Technologies: • Chemical Vapor Deposition •SputteredThin Film When your applications require exceptional pressure sensing performance and long-life reliability, look to Gems to deliver. From vacuum to 10,000 psig (-1 to 689 bar), we've got you covered with industry's largest selection and best choice of technologies. Our capacitance type sensors are ideal for high volume use; sputtered thin film types are the most precise pressure sensors you can buy, and our other types satisfy all requirements in between. Typical Applications • Off Highway Vehicles — Load Weighing Systems and Load Moment Indicating • Natural Gas Equipment — Compressors and Dispensing Equipment • Semiconductor Processing — Wafer Manufacturing • Power Plants — Piping Steam Pressures • Refrigeration — Compressors and Lube Oil Pressure Equipment • Robotics — Factory Automated Equipment • Test & Measurement — Dynamometers, Medical Instrumentation, Wind Tunnels • Barometrlcs — Altimeter Certification, Weather Stations • HVAC — Compressors, Filter Monitoring, Energy Management • Transportation — Breaking, Compressors, Lifts, Air Conditioning Chemical Vapor Deposition manufacturing methods bond a polysilicon layer to a stainless steel diaphragm at the molecular level to produce a sensor with superior long term drift performance. Common batch processing semiconductor manufacturing methods are used to create a polysilicon strain guage bridge with terrific performance at a very reasonable price. CVD construction offers excellent price/perfomance and is the most popular sensor for OEM applications. Sputtered Thin Film Type Sputtered film deposition creates transducers with maximum combined linearity hysteresis and repeatability. Accuracy is as high as 0.08% full scale with long term drift as low as 0.06% full scale per year. Phenomenal performance for critical instruments — Gems sputtered thin film transducers are the jewels of the pressure sensing industry. Capacitance Type Gems manufactures capacitance type pressure sensors for a wide range of high volume OEM and specialty applications. Detecting the capacitance change between two surfaces allows Gems transducers to sense extremely low pressure and vacuum levels. Robust construction allows these units to be used in a wide variety of applications. Coupled with an ASIC, these units provide good price/performance in a host of packaging styles. These transducers employ a micromachined silicon (MMS) diaphragm to detect pressure changes. The silicon diaphragm is protected from the media by an oil-filled 316SS isolation diaphragm; they react in tandem to process fluid pressure. MMS sensors utilize common semiconductor manufacturing techniques that allow for high proof pressure, good linearity, great thermal shock performance and stability in a thin sensor package. Contents_Page Start Visit www.GemsSensors.com for most current information.

Open the catalog to page 1

. Sensors & Controls Selection Guide ' Specific temperature capability depends on electrical connection selected. See specifications on respective product pages Visit www.GemsSensors.com for most current information.

Open the catalog to page 2

General Purpose Series 2200 Industrial Pressure Transducers ► Gauge, Absolute, Vacuum and Compound Pressure Models ► Submersible, General Purpose and Wash Down Enclosures ► High Stability Achieved by CVD Sensing Element ► Millivolt, Voltage and Current Output Models The 2200 series features stability and accuracy in a variety of enclosure options. The 2600 series extends the packaging options via an all welded stainless steel back end for demanding submersible and industrial applications. The 2200 and the 2600 feature proven CVD sensing technology, an ASIC (amplified units), and modular...

Open the catalog to page 3

. Sensors & Controls Individual Specifications Millivolt Output units Bridge resistance Voltage Output units Supply Voltage Sensitivity 0.01% FS/Volt Current Consumption Current Output units Supply Voltage Sensitivity 0.01% FS/Volt Electromagnetic Capability Meets the requirement for CE marking of EN50081 -2 Test Data: discharge, 4kV contact discharge. Unit survived. 1GHz, 1kHz mod. Maximum recorded output error • ENV50204 Radiated RF Susceptibility to Mobile Telephones. 10V/m, 900MHz. Maximum recorded for 1 minute. Unit survived. mod, 150kHz - 80MHz. Maximum recorded output Cable Legend:...

Open the catalog to page 4

Mini 4 Pin - With Connector Conduit Connector with Cable Conduit Connector with Flying Leads Moulded, Immersible Cable Amplified Gauge Amplified Absolute Amplified Gauge Amplified Absolute Code D-rfU— Visit www.GemsSensors.com for most current information.

Open the catalog to page 5

. Sensors & Controls Use the bold characters from the chart below to construct a product code Pressure Port- European Threads 19 - Plastic Nose Cone 29-Sink Weight Nose Cone Performance Code Apparatus Protection 2 - mV Only Transient Protection CE Mark, UR 3 - Amplified Only RFI Protected CE Mark, UR E - Amplified only IS mark (Div. 1 only)4 T - Amplified only IS mark (Div. 1 and 2)4 5 Electrical Connection (See Notes) A - 4 PIN DIN (Micro) Mating Connector Supplied B - 4 PIN DIN (Micro) Mating Connector Not Supplied D - Cable European Color Code F-Cable Gland Metal IP67 C - Fixed Plug Size...

Open the catalog to page 6

OEM Transducers Featuring Exceptional Proof Pressure and Stability Specifications ► Gauge, Vacuum, and Compound Pressure Models ► General Purpose and Wash down Enclosures High Proof Pressure Achieved by Thicker Diaphragm Construction ► Voltage and Current Output Models The 1200 Series features stability and toughness via its CVD and ASIC design coupled with a thicker diaphragm. The thicker diaphragm enables these sensors to survive most pressure spikes caused by pump ripple, solenoid valves, etc. The 1600 Series extends the packaging options by providing an all welded stainless steel back...

Open the catalog to page 7All Gems Sensors catalogs and brochures

-

D-Cryo Series Solenoid Valve

2 Pages

-

B-Cryo Series Solenoid Valve

2 Pages

-

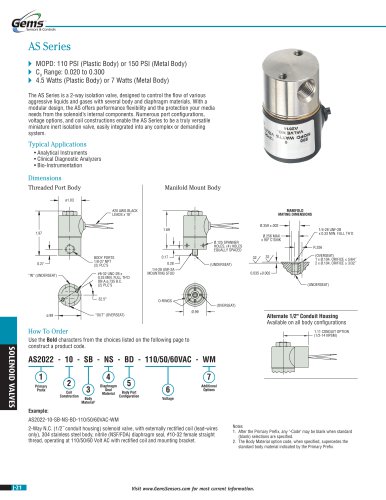

AS Series Solenoid Valve

2 Pages

-

BS Series Solenoid Valve

2 Pages

-

KM/KL Series Solenoid Valve

4 Pages

-

KV/KW Series Solenoid Valve

2 Pages

-

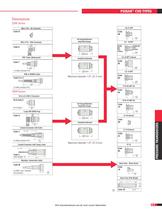

PM/PL Series

2 Pages

-

Gems Master Catalog Product

406 Pages

-

3600 Series

4 Pages

-

3800 Series

2 Pages

-

3500 Series

4 Pages

-

F Series

4 Pages

-

Appendix and Glossary

13 Pages

-

Pressure Transducers

67 Pages

-

Pressure Switches

30 Pages

-

Flow Switches

26 Pages

-

Warrick Conductivity Sensors

29 Pages

-

Level Sensors Continuous

33 Pages

-

Level Indicators Visual

27 Pages

-

Level Switches Multi-Point

26 Pages

-

Warrick_Conductivity_Sensors

29 Pages

-

Level_Sensors_Continuous-

33 Pages

-

Level_Indicators_Visual

27 Pages

-

Level Switches Single Point

43 Pages

-

Level_Switches_Mult-Point

26 Pages

-

Solenoid Valves

40 Pages

-

Flow Sensors

13 Pages

-

Electronic_Products-

13 Pages

-

J-Valves_05-16-2011opt

40 Pages

-

Proximity_Switches-

5 Pages

-

Flow_Switches

24 Pages

-

Pressure_Switches

28 Pages

-

Gems_ProdOverview_2008_Opt_Print

12 Pages

-

SemiconBroch

8 Pages

-

FS-380P Series

2 Pages