Catalog excerpts

Instruction Bulletin No. 198938 Rev A In-Line Flow Switches FS-380P Series Installation All NPT threads should be installed using a suitable thread sealant (Teflon tape or Permatex “No more Leaks”). Sealant must be kept out of unit during installation. Ten diameters of straight run piping are recommended upstream and downstream of the flow sensor. Body End Fitting Inlet Outlet Spring Specifications Wetted Materials Housing, End Fitting Piston Hydrolytically Stable Glass Reinforced Polypropylene PPS Composite 316 Stainless Steel Spring O-Ring Fluorcarbon 200 PSI at 70°F, 100 PSI at 212°F Oper. Pressure, Max. Operating Temperature FS-380P Flow Switches Can be Mounted In Various Positions Flow settings are based on a vertical position (inlet port down), using water at +70°F on increasing flow. Some variation in set point actuation will occur in other mounting orientations. -20°F to +212°F (100°C) 100 Micron or Better Required Filtration Set Point Accuracy Set Point Differential Switch, See “Switch Ratings” Inlet / Outlet Electrical Termination ±20%, Maximum 20% Maximum SPST, 10 VA 3/8” NPT Male or Quick Connect No. 24 AWG, 24” to 26” Polymeric Leads Note: The FS-380P is UL and CSA approved. Pressure Drop - Typical 16 14 Switch Ratings PSI Drop 12 Contact rating: 10W Switching Voltage (DC or AC Peak): 200 Max. Switching Current (DC or AC): 0.4 A Max. Carry Current (DC or AC): 0.4 A Max. Break down Voltage: 230 VDC Min. 10 8 6 4 Wiring Diagram 2 Normally Open 0 0 1 2 3 4 5 Flow Rate - GPM 6 7 8

Open the catalog to page 1

Dimensions 11/16” Hex. 3/8” NPT Ports 1” (25 mm) 4” (102 mm) 1” (25 mm) 11/16” Hex. O-Ring Typ. Quick Disconnect Ports .75” (19 mm) Across Flats .43” (11 mm) Dia. Typ. 4.22” (107 mm) Important Points: • Gems products must be maintained and installed in strict accordance with the National Electrical Code and the applicable Gems product instruction Bulletin that covers installation, operation and proper maintenance. Failure to observe this information may result in serious injury or damages. • For hazardous area applications involving such things as, but not limited to, ignitable mixtures,...

Open the catalog to page 2All Gems Sensors catalogs and brochures

-

D-Cryo Series Solenoid Valve

2 Pages

-

B-Cryo Series Solenoid Valve

2 Pages

-

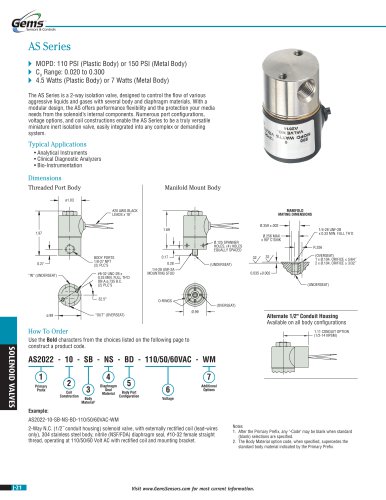

AS Series Solenoid Valve

2 Pages

-

BS Series Solenoid Valve

2 Pages

-

KM/KL Series Solenoid Valve

4 Pages

-

KV/KW Series Solenoid Valve

2 Pages

-

PM/PL Series

2 Pages

-

Gems Master Catalog Product

406 Pages

-

3600 Series

4 Pages

-

3800 Series

2 Pages

-

3500 Series

4 Pages

-

F Series

4 Pages

-

Appendix and Glossary

13 Pages

-

Pressure Transducers

67 Pages

-

Pressure Switches

30 Pages

-

Flow Switches

26 Pages

-

Warrick Conductivity Sensors

29 Pages

-

Level Sensors Continuous

33 Pages

-

Level Indicators Visual

27 Pages

-

Level Switches Multi-Point

26 Pages

-

Warrick_Conductivity_Sensors

29 Pages

-

Level_Sensors_Continuous-

33 Pages

-

Level_Indicators_Visual

27 Pages

-

Level Switches Single Point

43 Pages

-

Level_Switches_Mult-Point

26 Pages

-

Solenoid Valves

40 Pages

-

Flow Sensors

13 Pages

-

Electronic_Products-

13 Pages

-

J-Valves_05-16-2011opt

40 Pages

-

Proximity_Switches-

5 Pages

-

Flow_Switches

24 Pages

-

Pressure_Switches

28 Pages

-

Pressure_Transducers-5-16-2011

44 Pages

-

Gems_ProdOverview_2008_Opt_Print

12 Pages

-

SemiconBroch

8 Pages