Catalog excerpts

VERTICAL SYSTEM OWNERS MANUAL STANDARD SYSTEM FEATURES INSTALLATION INSTRUCTIONS OPERATION INSTRUCTIONS MEMBRANE CLEANING PROCEDURE MAINTENANCE TIMETABLE PRESSURE VESSEL END PLUG CHANGING PROCEDURE ELECTRICAL DIAGRAM TROUBLESHOOTING GUIDE HIGH PRESSURE PUMP SERVICE INSTRUCTIONS LIMITED WARRANTY

Open the catalog to page 1

Thank you for choosing an ECHO Tec. reverse osmosis desalination system. We trust that you will be completely satisfied with our product. The purpose of this manual is to allow you to become familiar with each component of your new ECHO Tec. desalination system. By understanding the function, importance and normal operation of each part in the system, the operator can readily diagnose problems when they first develop. Such problems are easily corrected and require minor adjustments. If left unattended, a small problem in one component will affect the rest of the system and can lead to an...

Open the catalog to page 2

Rated Performance! Reverse Osmosis performance varies with the feed water temperature and salinity. The rated performance is tested at 26°C / 80°F water temperature at a salinity of 35g/l. A decrease in product water quantity of 10 to 15% in the first year is normal and expected. Standard size high rejection TFC Polyamide, thin film composite, spiral wound, single pass reverse osmosis element. Salinity Range- System 500 / 900: up to 50,000 ppm TDS ( NaCl ) Chlorine Tolerance: 1000 ppm hours Operating Pressure: 800-850 psi (continuous duty) Feed Water Pressure: 0 to 60 psi Feed Water...

Open the catalog to page 3

STANDARD SYSTEM FEATURES Fully assembled desalination system in aluminum vertical flame with shock mounted 316Ti high pressure pump, control panels, RO vessels and 5 and 20 micron cartridge filtration system 1 Fresh water flush kit with hose and 316SS hose clamps 1 Product water tube 10ft / 3m 1 Intake hose 3/4" 10ft / 3m (braided) with 2pcs 316SS hose clamps 1 Intake hose 3/4" 3.3ft / lm (wire coil reinforced) with 2pcs 316SS hose clamps 1 Service intake hose 5/8" 3ft / lm with lpc 316SS hose clamp 1 Biocide solution, 1 acid cleaning solution, 1 alkaline cleaning solution

Open the catalog to page 4

INSTALLATION INSTRUCTIONS Position the desalination system in a cool and dry location. Mount the system using all four mounting The electrical installation should only be done by a professional electrician. Check the correct voltage before installing the system. The cable labeled with the system's voltage and frequency is to be connected to the power supply. The cable marked "FEED PUMP" is to be connected to the feed pump or should be insulated / removed where pressurized seawater is available. SEAWATER FEED PUMP (Optional Equipment) Mount the feed pump in a dry location below the waterline...

Open the catalog to page 5

SYSTEM OPERATION INSTRUCTIONS The reverse osmosis membrane contains a preservative solution to prevent microbiological growth. If ingested, may cause irritation of the gastro-intestinal tract, colic, diarrhea, or other similar symptoms. Therefore, discard all the product water for at least thirty minutes of initial operation or after storage before drinking or use in food preparations! Do not operate the system using contaminated feed water sources (oil, chlorine or other Have you filled the high-pressure pump with the proper amount of oil (SAE90 gearbox oil)? 1) Open the seacock and the...

Open the catalog to page 6

FRESH WATER FLUSH PROCEDURE Caution: The fresh water pressure should not exceed the range of the low pressure gauge/s. The installation of a pressure reducer may be necessary. You should fresh water flush your watermaker after every use or infuse a biocide solution for long term storage. The fresh water flush prepares your watermaker for a shut down period of seven days maximum. You can repeat the flush procedure every seven days, to extend the short term storage. 1) Open the pressure control-valve all the way counter-clockwise. 2) Close the shut off valve on the pre-filter assembly and...

Open the catalog to page 7

MEMBRANE CLEANING PROCEDURE The membranes of the ECHO Tec. Watermaker must be chemically cleaned when the product water output drops by 20% of the specified amount. The frequency of this occurring will vary greatly depending upon feed water. Fouling of the membranes will naturally occur during normal usage of the ECHO Tec. Watermaker. Increased amounts of fouling without proper cleaning of the membrane will reduce the performance of your water maker. Cleaning of the membranes will not enhance the quality (TDS reading) of the product water. CAUTION: The use of chemicals or cleaning methods...

Open the catalog to page 8

MAINTENANCE TIMETABLE The following maintenance timetable is an estimate of the time intervals at which maintenance may be required only. This schedule must be adjusted to the regularity of usage, the condition of the intake water, the length of time the system is exposed to seawater and the total running time following each system cleaning. TIME INTERVAL INTERMITTENT DUTY Seawater intake Inspect and clean intake. Replace or clean elements and clean housings. When system intake pressure Charcoal flush filter Replace element. High pressure pump Change crankcase oil. Initial change after 50...

Open the catalog to page 9

MEMBRANE CHANGING PROCEDURE PRESSURE VESSEL END PLUG CHANGING PROCEDURE 1) Remove the product port (if installed) and the high pressure fitting. 2) Remove the two/three M6 bolts. 3) Remove the two/tree locking plates (locks) 4) Remove the backing plate 5) Pull the end plug with the aid of a hand tight inserted product port in one fast pull. Should the plugs O-ring (PLOl)get stuck in the groove of the pressure vessel, it will be more difficult to pull the plug. If the plug gets stuck, tap it in, apply silicone lubricant to the vessel's inner wall and remove it in one fast pull. 6) Inspect...

Open the catalog to page 10

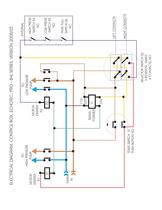

MAIN IN R1 MOTOR STARTER R1 START SWITCH S1 PUSH BUTTON NO TO HIGH PRESSURE PUMP TRANSFORMER MOTOR STARTER R2 24V T1 110/ 220V R2 SELECTOR SWITCH S2 3-POSITION, MAINT. 4 CONTACTS, NO TO LOW PRESSURE PUMP RIGHT CONTACTS LEFT CONTACTS TANK FULL SWITCH S6 NC LOW PRESS. SWITCH S5 NO HIGH PRESS. SWITCH S4 NC EXTERNAL ELECTRICAL DIAGRAM, CONTROL BOX, ECHOTEC. PRO - BHL SERIES, VERSION 2008/03

Open the catalog to page 11Archived catalogs

-

MODULAR SERIES (BELT DRIVEN)

21 Pages

-

DC manual

21 Pages