Website:

DIAB Group

Website:

DIAB Group

Catalog excerpts

AT THE CORE OF YOUR PERFORMANCE KITTING

Open the catalog to page 1

OPTIMIZE EFFICIENCY, COST, WEIGHT, AND QUALITY WITH DIAB KITTING SOLUTIONS WHAT IS A KIT? A Diab kit is a tailor-shaped set of core elements. • Decrease moulded weight with improved surface quality. The kit can consist of simple pre-cut core panels or • Reduce finishing work on laminate complex 3D shapes made with CNC routing. Each • Minimize the amount of waste handling piece is pre-cut and then numbered to fit precisely • Simplify internal logistics and reduce into its designated place in the mould. Kits are designed based on your application’s requirements stock items • Recover factory...

Open the catalog to page 2

AN OPTIMIZED KIT FOR EVERY TYPE OF MANUFACTURING PROCESS Together with the expected performance of the end product, it is crucial to analyze the manufacturing process used. curvature of the mould influence which core finishing selection fits best into the mould shape COMPOSITE MANUFACTURING PROCESS with a minimum of spring back and reduced resin The manufacturing process defines what finishing consumption. Full sandwich core coverage or for form and flow we will use for the core going allowing selected single skin areas will also into the kits and which kit option we decide to use....

Open the catalog to page 3

ADVANCED KITTING FOR MAXIMUM WEIGHT-SAVING & PERFORMANCE Diab innovative Advanced kits offer a lower weight, an optimized fit in the mould, reduced resin • Lower resin consumption, up to 50-75 % less Advanced kitting is the optimal solution where weight, resin usage, and surface finishing are consumption, improved fit and handling performance, and improved cosmetics for infusion and prepreg • Reduced structural weight. critical. Sailing boats, powerboats, yachts, applications. Combining Diab’s extensive knowledge • Improved surface quality due to an intact foam simulators, antennas,...

Open the catalog to page 4

THE DIAB KIT PROCESS– TEAMING UP WITH YOU FOR SUCCESS 1 Our Sales team and Application Center will work together with you all the way. PREPARATION & BASIS • Spend some time thinking about the critical success factors for your application. • Specify the core thicknesses and core teaming with you for success properties from the structural design. Diab can also assist with structural engineering. • A 3D model or detailed 2D drawings, along with notes, are usually enough to start the kit design process. Ideally, you provide a core drawing or Design proposal and cost estimation Final kit design...

Open the catalog to page 5

DIAB APPLICATION CENTER Realising the total value of composite designs Diab Application Center is our powerful team with we ensure that you can realize the total value of COMPOSITE PART & PROTOTYPE engineers, product specialists, and process composite designs. specialists ready to team up with you to realize the CCG consists of mechanical and process Prototyping and short production runs have high total value of composites. Diab Application Center engineers, material scientists, naval architects, and investment costs and can limit other daily also creates the kit designs in close...

Open the catalog to page 6

Diab Group (HEAD OFFICE) Drottninggatan 7, 5th floor SE-252 21 Helsingborg, Sweden Diab Kitting brochure Jan 2024 Diab is a world leader in sandwich composite solutions that make customers’ products stronger, lighter and smarter. Diab provides a range of core materials, cost-effective kits and finishings, along with in-depth knowledge on composites. Diab also provides engineering services for composite technology through Composites Consulting Group (CCG). Diab is a participant in the UN Global Compact. Subject to possible printing errors and changes.

Open the catalog to page 7All DIAB Group catalogs and brochures

-

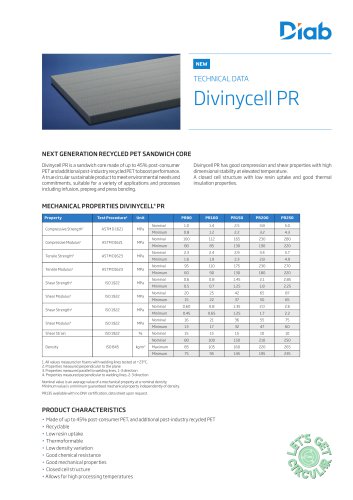

DIVINYCELL PR

2 Pages

-

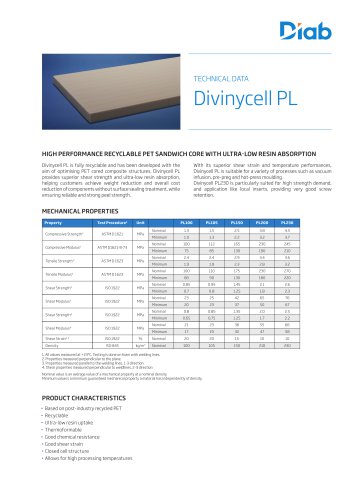

DIVINYCELL PL

2 Pages

-

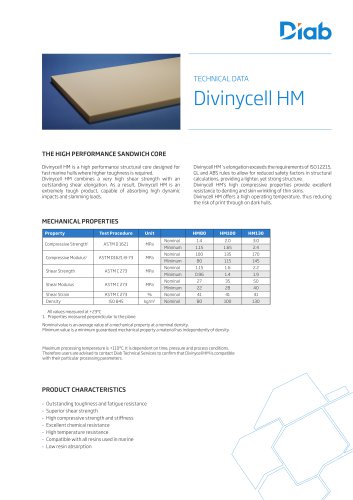

DIVINYCELL HM

2 Pages

-

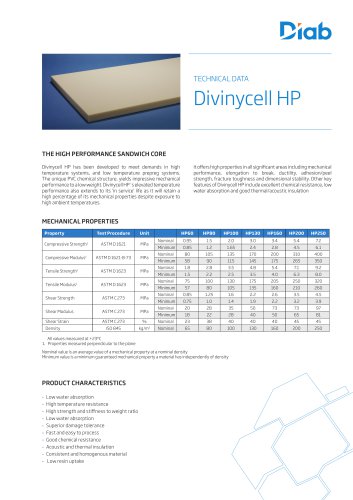

DIVINYCELL HP

2 Pages

-

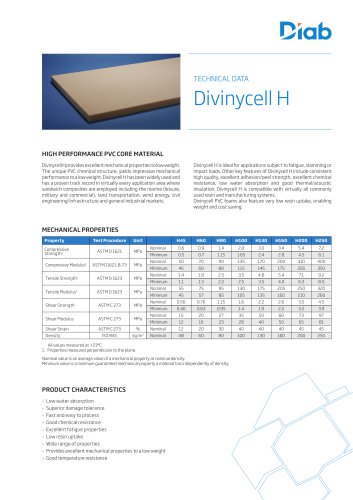

DIVINYCELL H

2 Pages