Website:

CaviDyne

Website:

CaviDyne

Catalog excerpts

Read all safety precautions and instructions carefully before operating equipment. Refer to operating instruction of equipment that this engine powers. Ensure engine is stopped and level before performing any maintenance or service. Safety Maintenance Specifications Tools and Aids Troubleshooting Air Cleaner/Intake Fuel System Governor System Lubrication System Electrical System Starter System Gear Reduction System Disassembly/Inspection and Service Reassembly

Open the catalog to page 1

Safety SAFETY PRECAUTIONS WARNING: A hazard that could result in death, serious injury, or substantial property damage. CAUTION: A hazard that could result in minor personal injury or property damage. NOTE: is used to notify people of important installation, operation, or maintenance information. WARNING Explosive Fuel can cause fires and severe burns. Do not fill fuel tank while engine is hot or running. Gasoline is extremely flammable and its vapors can explode if ignited. Store gasoline only in approved containers, in well ventilated, unoccupied buildings, away from sparks or flames. Spilled...

Open the catalog to page 2

Maintenance MAINTENANCE INSTRUCTIONS WARNING Accidental Starts can cause severe injury or death. Disconnect and ground spark plug lead(s) before servicing. Before working on engine or equipment, disable engine as follows: 1) Disconnect spark plug lead(s). 2) Disconnect negative (–) battery cable from battery. Normal maintenance, replacement or repair of emission control devices and systems may be performed by any repair establishment or individual; however, warranty repairs must be performed by a Kohler authorized dealer. MAINTENANCE SCHEDULE After first 5 Hours ● Change oil. Lubrication...

Open the catalog to page 3

Maintenance OIL RECOMMENDATIONS We recommend use of Kohler oils for best performance. Other high-quality detergent oils (including synthetic) of API (American Petroleum Institute) service class SJ or higher are acceptable. Select viscosity based on air temperature at time of operation as shown in table below. STORAGE If engine will be out of service for 2 months or more follow procedure below. 1. Add Kohler PRO Series fuel treatment or equivalent to fuel tank. Run engine 2-3 minutes to get stabilized fuel into fuel system (failures due to untreated fuel are not warrantable). 2. Change oil...

Open the catalog to page 4

Specifications CH260/CH270 Engine Dimensions Dimensions in millimeters. Inch equivalents shown in [ ].

Open the catalog to page 5

Specifications CH260/CH270 Engine Dimensions Dimensions in millimeters. Inch equivalents shown in [ ].

Open the catalog to page 6

Specifications CH395 Engine Dimensions Dimensions in millimeters. Inch equivalents shown in [ ].

Open the catalog to page 7

Specifications CH395 Engine Dimensions Dimensions in millimeters. Inch equivalents shown in [ ].

Open the catalog to page 8

Specifications CH440 Engine Dimensions Dimensions in millimeters. Inch equivalents shown in [ ].

Open the catalog to page 9

Specifications CH440 Engine Dimensions Dimensions in millimeters. Inch equivalents shown in [ ].

Open the catalog to page 10

Specifications ENGINE IDENTIFICATION NUMBERS Kohler engine identification numbers (model, specification and serial) should be referenced for efficient repair, ordering correct parts, and engine replacement. Model . . . . . . . . . . . . . . . . . . . . . CH260 Command Engine Horizontal Shaft Numerical Designation Specification . . . . . . . . . . . . . . . CH260-0001 Serial . . . . . . . . . . . . . . . . . . . . . 4423500328 Year Manufactured Code Code Year 44 2014 45 2015 46 2016 GENERAL SPECIFICATIONS3,6 Bore Stroke Displacement Oil Capacity (refill) Maximum Angle of Operation (@ full oil...

Open the catalog to page 11

Crankcase Oil Drain Plug Closure Plate Screw Cylinder Head Fastener (torque in 2 increments) Electric Starter Mounting Screw Electric Starter Drive CH440 Type II Starter Assembly Screw 5 mm Brush Lead Connector Wire Screw 4 mm Electric Starter Relay (Solenoid) CH395, CH440 Mounting Screw Nut Fuel Tank Mounting Nut Mounting Screw Inlet Fitting Gear Reduction M6 Screws M8 Screws Governor (Electronic) Electronic Governor Control to Crankcase Governor (Mechanical) Lever Nut Throttle Control Lever Nut Values are in Metric units. Values in parentheses are English equivalents. Lubricate threads...

Open the catalog to page 12

Ignition Spark Plug Module Fastener Oil Sentry™ Float Switch Screw Oil Sentry™ Module Screw Oil Sentry™ Wire Lead Nut Retractable Starter Cover Screw Center Screw Rocker Arm Stud Pivot Jam Nut Valve Cover Fastener Camshaft Running Clearance Camshaft Bearing Surface O.D. New Max. Wear Limit Cam Lobe Profile (minimum dimension, measured from base circle to top of lobe) Intake - New Max. Wear Limit Exhaust - New Max. Wear Limit Muffler Exhaust Screw M8 M10 Muffler Shield Screw M6 M4 Spark Arrestor Screw M5 Values are in Metric units. Values in parentheses are English equivalents. Lubricate...

Open the catalog to page 13

Connecting Rod-to-Crankpin Side Clearance New Max. Wear Limit Connecting Rod-to-Piston Pin Running Clearance Max. Wear Limit Crankcase Governor Cross Shaft Bore I.D. New Max. Wear Limit Crankshaft End Play (free) Ball Bearing Internal Clearance Crankshaft O.D. (new) PTO end Flywheel end Connecting Rod Journal O.D. New Max. Wear Limit Max. Taper Max. Out-of-Round Width Runout (either end) Main Bearing I.D. (Crankcase/Closure Plate) New (installed) Cylinder Bore Bore I.D. New Max. Wear Limit Max. Out-of-Round Max. Taper 0.0508/0.254 mm (0.002/0.010 in.) 0.003/0.025 mm 0.005/0.020 mm...

Open the catalog to page 14

Cylinder Head Max. Out-of-Flatness Governor (Mechanical) Governor Cross Shaft -to-Crankcase Running Clearance Governor Cross Shaft O.D. New Max. Wear Limit Piston, Piston Rings, and Piston Pin Piston-to-Piston Pin Running Clearance Max. Wear Limit Piston Pin O.D. New Max. Wear Limit Top and Center Compression Ring Side Clearance New Bore Ignition Spark Plug Gap Module Air Gap Top Compression Ring End Gap New Bore Used Bore (Max.) Center Compression Ring End Gap New Bore Used Bore (Max.) Governor Gear Shaft -to-Governor Gear Running Clearance Governor Gear Shaft O.D. New Max. Wear Limit...

Open the catalog to page 15

Piston, Piston Rings, and Piston Pin (continued) Oil Control Ring-to-Groove Side Clearance Piston Thrust Face O.D. New Max. Wear Limit Piston Thrust Face-to-Cylinder Bore Running Clearance Valves and Valve Tappets Intake and Exhaust Valve Lash Intake Valve Stem-to-Valve Guide Running Clearance 0.0762/0.127 mm (0.003/0.005 in.) 0.038/0.065 mm 0.025/0.055 mm (0.0010/0.0022 in.) (0.0015/0.0026 in.) Exhaust Valve Stem-to-Valve Guide Running Clearance 0.085/0.112 mm 0.040/0.07 mm (0.0016/0.0028 in.) (0.0033/0.0044 in.) Intake Valve Stem O.D. 5.50 mm 6.57 mm (0.259 in.) New (0.217 in.) Max. Wear...

Open the catalog to page 16All CaviDyne catalogs and brochures

-

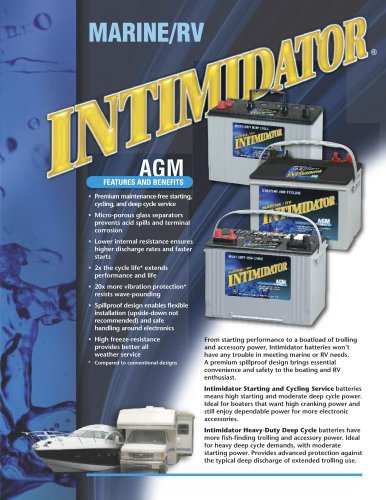

AGMIntimidator Battery

2 Pages

-

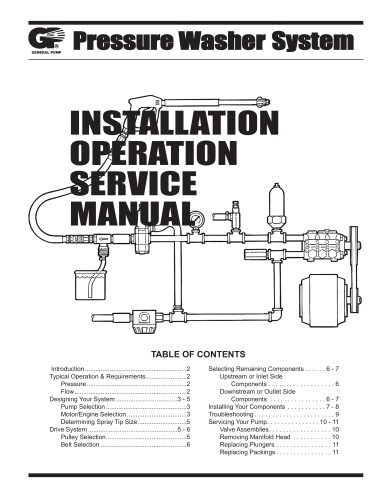

Plunger Pumps

20 Pages

-

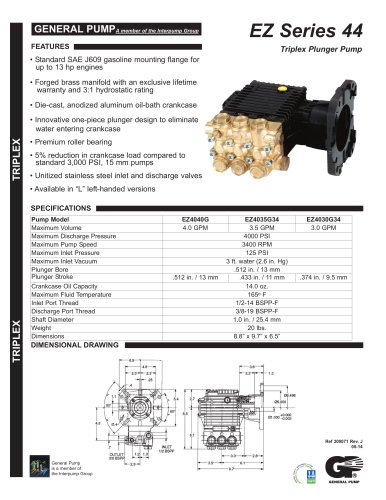

T RIP L E X

2 Pages

-

CaviBlaster 0625-G

1 Pages

-

CaviBlaster 1030-ROV

1 Pages