Catalog excerpts

Anti-corrosion high thickness epoxy filler containing aluminium, specifically studied to obtain waterproof metal surfaces. This product can boast excellent physical characteristics such as adhesion, hardness and abrasion resistance. Product information Finish Colour Solids (by volume) Specific gravity Flash point VOC (average calculated content) Packaging Semi-gloss Aluminum.202 ASTM D2369 UNI EN ISO 2811-1 UNI EN ISO 13736 ISO 11890-2/2006 16 Lt (base 11,5 Lt. + cat 4,5 Lt.) Application and use SURFACE PREPARATION Pressure wash with fresh water and remove any trace of oil and grease. All surfaces to be painted must be clean, dry and free of contaminants (if necessary, assess the level of cleanliness through the Bresle ISO 8502-6 method). Apply on adequate and in good condition primers. If covering times are overcome, sandpaper the primer before applying Epotar Free. Boero Bartolomeo S.p.A. Via Macaggi 19 - 16121 Genova, Italia - Tel. +39 010 55001 - Fax +39 010 5500.291 www.boeroyachcoatings.com - info@boeroyachtcoatings.com RijR© ISO 9001 - ISO 14001 BSOHSAS18001

Open the catalog to page 1

Mixing ratio by volume Mixing ratio by weight Base (comp. A) 663.202 Hardener B) 663.000C Pot-life N.B: do not use this product when Pot-life time is exceeded Thinner/Tool cleaning N.B: the indicated dilution % is considered on the catalysed product Application methods 693 - Roller/Brush (10% max) 693 - Conventional spray/Airless: (10% max) Conventional Pressure 3,5 bar Nozzle 1,9 - 2,2 mm Airless Pressure 150 bar Nozzle 0,3 - 0,6 mm Angular range: 65° - 80° Dry film thickness per coat Standard application range Wet film thickness per coat Standard application range Theoretical coverage...

Open the catalog to page 2

EPOTAR FREE TECHNICAL DATA SHEET Recommended primers Notes This product is provided in two cans to be completely and carefully mixed together before use. The potential dilution must be performed after mixing the two components. Physical data of two-component products refer to components that have been already mixed. Drying time Temperature °C Coverage Epoxy or polyester products Sanding Full curing N.B. The drying times and the overcoating intervals increase with higher thickness of the applied film. Always check that the existing film is perfectly dry before applying a further product coat...

Open the catalog to page 3

EPOTAR FREE TECHNICAL DATA SHEET Storage It is recommended to avoid exposure to air and extreme temperatures. To maximize the shelf life in the can, it is worth checking that the container is well closed during the storage and the temperature is between 10° C and 35° C. Avoid exposure to direct sunlight. Safety rules Observe the provisions of DPR 303 and 547. Avoid contact with the skin, for example. Operate in well ventilated places and, if in closed areas, use vacuum cleaners, fans and air conveyors. During the application, use appropriate protections (masks, gloves, glasses, etc.)....

Open the catalog to page 4All Boero YachtCoatings catalogs and brochures

-

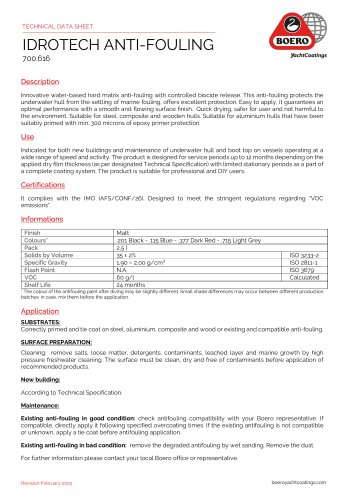

IDROTECH ANTI-FOULING

3 Pages

-

Superyacht Brochure

29 Pages

-

2024 TECHNICAL PRODUCT CATALOGUE

15 Pages

-

BYC Colour Card

2 Pages

Archived catalogs

-

PITTURA PER COPERTA

5 Pages

-

Range Evolving

3 Pages

-

CC Antifouling

4 Pages

-

Challenger HI Solid

6 Pages

-

CC Challenger PRO SE

4 Pages

-

EPOYACHT

3 Pages

-

Brochure ChallengerMix

24 Pages

-

MAGELLAN 630

2 Pages

-

Brochure Superyachts

13 Pages

-

CC COLOURS

6 Pages

-

BYC_Catalogue_2014

56 Pages