Catalog excerpts

WAKEFIELD EQUALISATION REDUCTION OF PROPELLER HUB VORTEX CONTRA-ROTATING SWIRL The Becker Mewis Duct® straightens and accelerates the hull’s wake into the propeller and also produces net forward thrust. An improved slipstream behind the duct significantly reduces the hub vortex with a corresponding reduction in thrust, leading to improved thrust and inflow to the rudder. Due to individually placed fins, a pre-swirl counter to the direction of propeller operation is generated, recovering rotational energy from the slipstream. BECKER PERFORMANCE PACKAGE (BPP) The combination of a Becker Rudder and Becker Mewis Duct® or Becker Mewis Duct® Twisted enables maximum possible energy savings in front of and behind the propeller. Both products are available from a single company and are thus perfectly harmonised via Computational Fluid Dynamics (CFD) calculations for optimised manoeuvring and maximum energy savings. propeller, the reduction of losses, the pre-swirl and the passive part for minimising drag and improving course stability. Becker Marine Systems constantly reviews the best combinations of a Becker Mewis Duct® or Becker Mewis Duct® Twisted with a rudder system such as the Becker Flap, Becker Twist or Becker Schilling® Rudder, resulting in the best combination of manoeuvrability and efficiency. The total performance improvement is based on two parts, the active part related to the improvement of flow towards the The combination of the Becker Mewis Duct® with a Becker Rudder dramatically increases the efficiency of the system by means of wakefield optimisation and lower rudder resistance with improved manoeuvring performance. ENERGY-SAVING DEVICES The Becker Mewis Duct® combines all three of the principles above in a non-linear interaction: The Becker Mewis Duct® harmonises and stabilises flow and generates a pre-swirl to reduce the rotational losses in the propeller slipstream. The integrated fins have a stator effect by generating a pre-swirl counter to the direction of propeller operation. This generates more thrust. The fins are asymmetrically profiled and arranged to generate a perfectly homogenous flow distribution. ALL IN ONE – BECKER MEWIS DUCT® ADVANTAGES: • Optimised rudder profile • Reduced weight • No cast parts • Less cavitation • Reduction of rotational losses • Improved propulsion efficiency • Minimised drag • Improved course keeping • Power savings • Reduced wear and tear • Best propeller coverage • Reduced vibration ESPECIALLY SUITED FOR: • Container feeders • Container liners • Tankers • Shuttle tankers • LNG/LPG carriers • Bulk carriers • General cargo carriers/ Heavy lifters • Car carriers • ConRo/RoRo • Ferries • Navy ships Manoeuvring Systems COMBINED ENERGY SAVINGS With a record of improving rudder efficiency as its core mission, Becker Marine Systems began development of a new energysaving device intended to be better than anything else then available on the market. With maximum energy savings resulting from the Becker Rudder and a Becker Mewis Duct® or Becker Mews Duct® Twisted, the BPP can be applied to almost any hull form as well as virtually any propeller. With the BPP clients such as shipyards, ship designers and ship owners/managers have the opportunity to apply a tailor-made and advanced energy-saving solution in order to achieve significant efficiency gains for a given hull form and given propeller design and by doing so close a gap in required ship speed or achieve a specific required power savings. XVI Energy-Saving Devices Manoeuvring Systems Energy-Saving Devices Development began in 2008 and shortly thereafter the first Becker Mewis Duct® was produced and installed on an open hatch cargo carrier. The initial idea was to install the duct on tankers and bulkers, but due to its success in achieving average power savings of 6.5%, Becker Marine Systems was approached by the owners of other types of ships (general cargo vessels, multi-purpose vessels, heavy lifters and more) about ordering a Becker Mewis Duct®. Every contract includes a provision with a power-savings guarantee to be verified by a model test. If the model test does not demonstrate the level of agreed power savings, the owner may withdraw from the contract. Manoeuvring Systems Energy-Saving Devices Then, in 2012 Becker was asked by the German owner of a container ship fleet to develop an energy-saving device for faster vessels such as container ships. This heralded the birth of the Becker Mewis Duct® Twisted (formerly known as the Becker Twisted Fin®). Since that time Becker has been supplying the Becker Mewis Duct® and Becker Mewis Duct® Twisted to every major shipowner in the world. Becker Marine Systems has a very strong CFD team that custom designs Becker’s energy-saving devices for each specific hull/propeller configuration. This experience enables Becker Marine Systems to offer a complete performance package including a Becker energy-saving device and a Becker rudder, designed and optimised to achieve maximum efficiency combined with the highest level of m

Open the catalog to page 1

BECKER MEWIS DUCT BECKER MEWIS DUCT® TWISTED POTENTIAL SAVINGS AND THE CORRELATION BETWEEN POWER SAVINGS AND SHIP SIZE The Becker Mewis Duct® is an energy-saving device developed for full-form slower ships enabling either significant power savings at a given speed or, alternatively, the vessel to travel faster at a given power level. The Becker Mewis Duct® consists of two strong fixed elements mounted on the vessel: a duct positioned in front of the propeller along with an integrated fin system. The duct straightens and accelerates the hull wake into the propeller and also produces a net...

Open the catalog to page 2All Becker Marine Systems catalogs and brochures

-

LNG Hybrid Concepts

2 Pages

-

Becker Marine Products

19 Pages

-

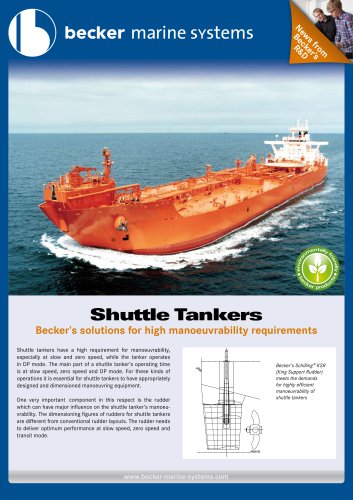

Shuttle tankers

2 Pages

-

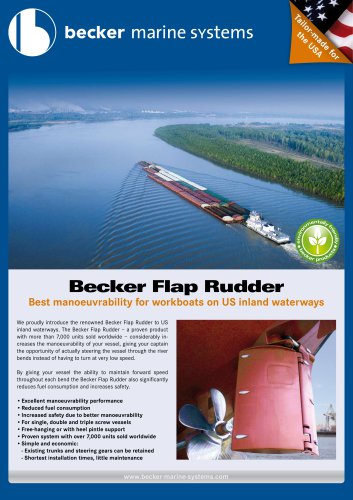

Becker Flap Rudder

2 Pages

-

Becker Bulb Rudders

4 Pages

-

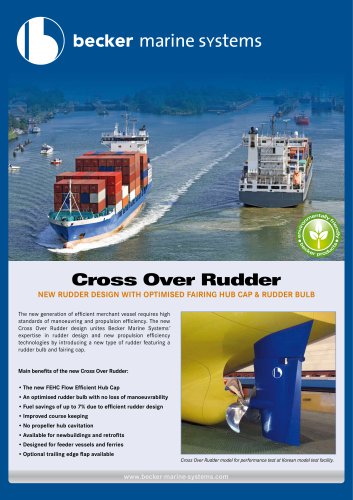

Becker Cross Over Rudder

2 Pages

-

Becker Mewis Duct Brochure

17 Pages

-

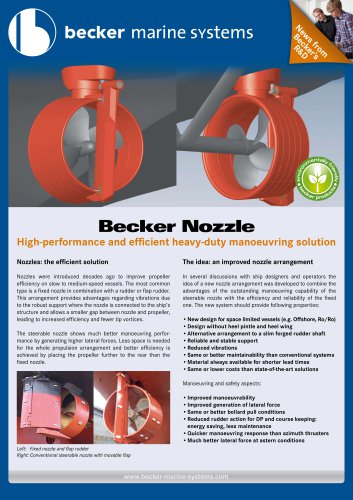

Becker Nozzle

2 Pages

-

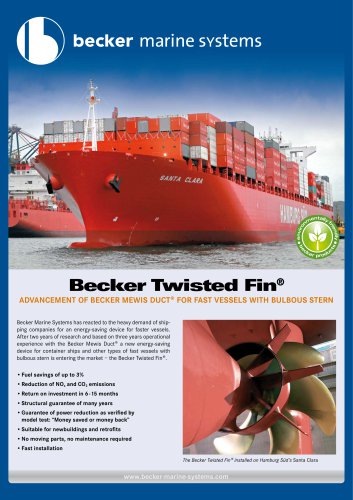

Becker Twisted Fin®

4 Pages

Archived catalogs

-

propeller nozzle for ships

4 Pages

-

flap rudder for ships

41 Pages