Catalog excerpts

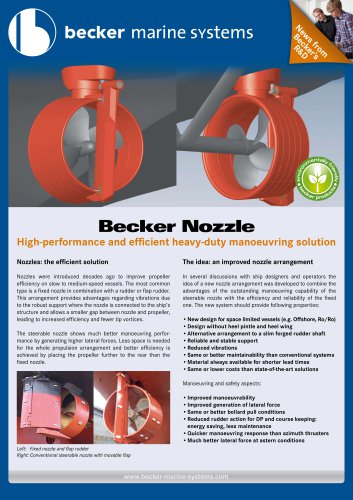

Becker Nozzle High-performance and efficient heavy-duty manoeuvring solution Nozzles: the efficient solution The idea: an improved nozzle arrangement Nozzles were introduced decades ago to improve propeller efficiency on slow to medium-speed vessels. The most common type is a fixed nozzle in combination with a rudder or flap rudder. This arrangement provides advantages regarding vibrations due to the robust support where the nozzle is connected to the ship’s structure and allows a smaller gap between nozzle and propeller, leading to increased efficiency and fewer tip vortices. In several discussions with ship designers and operators the idea of a new nozzle arrangement was developed to combine the advantages of the outstanding manoeuvring capability of the steerable nozzle with the efficiency and reliability of the fixed one. The new system should provide following properties: The steerable nozzle shows much better manoeuvring performance by generating higher lateral forces. Less space is needed for the whole propulsion arrangement and better efficiency is achieved by placing the propeller further to the rear than the fixed nozzle. • New design for space limited vessels (e.g. Offshore, Ro/Ro) • Design without heel pintle and heel wing • Alternative arrangement to a slim forged rudder shaft • Reliable and stable support • Reduced vibrations • Same or better maintainability than conventional systems • Material always available for shorter lead times • Same or lower costs than state-of-the-art solutions Manoeuvring and safety aspects: • Improved manoeuvrability • Improved generation of lateral force • Same or better bollard pull conditions • Reduced rudder action for DP and course keeping: energy saving, less maintenance • Quicker manoeuvring response than azimuth thrusters • Much better lateral force at astern conditions Left: Fixed nozzle and flap rudder Right: Conventional steerable nozzle with movable flap

Open the catalog to page 1

Becker Nozzle Performance comparison Nozzle design For comparison three design cases were defined: two representing the standard cases of fixed and steerable nozzles and a new steerable nozzle without heel support, but much stronger bearing arrangement at the top. The study was divided into the system components of the hull (including heel support, if applied), nozzle and rudder/flap. The targets of a heel support free design on a steerable nozzle places special requirements on the upper support and bearing design. The experience from bearing solutions of high-loaded rudder systems enables...

Open the catalog to page 2All Becker Marine Systems catalogs and brochures

-

Energy-Saving Devices

2 Pages

-

LNG Hybrid Concepts

2 Pages

-

Becker Marine Products

19 Pages

-

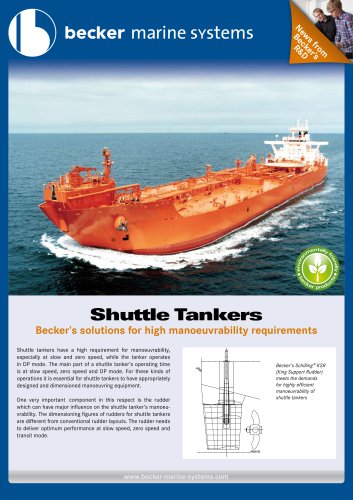

Shuttle tankers

2 Pages

-

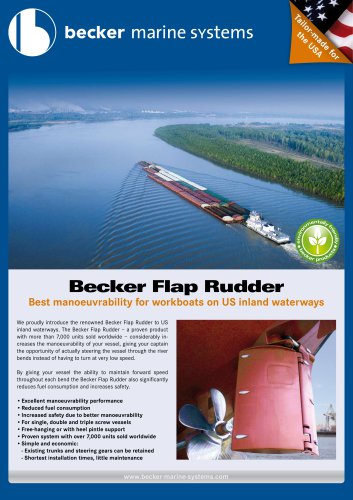

Becker Flap Rudder

2 Pages

-

Becker Bulb Rudders

4 Pages

-

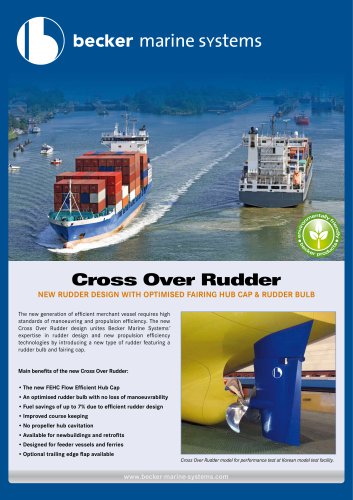

Becker Cross Over Rudder

2 Pages

-

Becker Mewis Duct Brochure

17 Pages

-

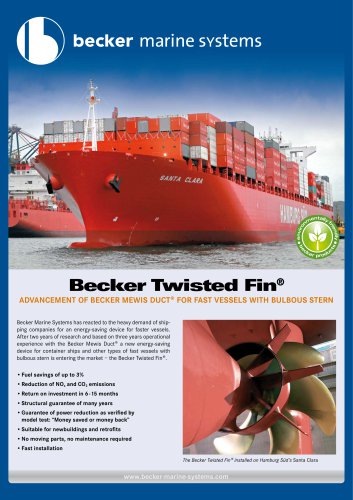

Becker Twisted Fin®

4 Pages

Archived catalogs

-

propeller nozzle for ships

4 Pages

-

flap rudder for ships

41 Pages