Catalog excerpts

becker mewis duct®

Open the catalog to page 1

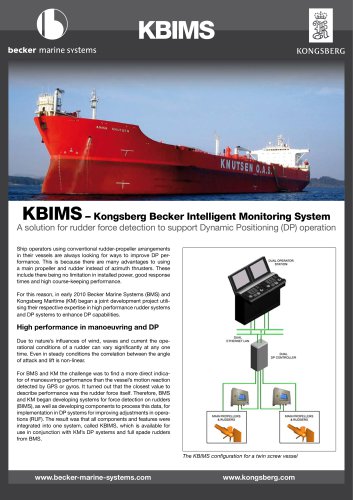

About us Established in 1946 and located in Hamburg, Germany, Becker Marine Systems is a leading supplier of high-performance rudders and manoeuvring systems for all types and sizes of vessels. Our extensive range of rudder profiles and configurations allows us to design any manoeuvring system tailored to your needs and requirements. Our well-known products such as the Flap Rudder, the TLKSR® Twisted Rudder and the Becker Mewis Duct® are based on over 60 years of successful business in the world’s shipping and shipbuilding industry. In this brochure we are pleased to present one of our...

Open the catalog to page 2

The Becker Mewis Duct® The Becker Mewis Duct® is a novel power-saving device which has been developed for full-form slower ships that allows either significant fuel savings at a given speed or alternatively for the vessel to travel faster for a given power level. The Becker Mewis Duct® consists of two strong fixed elements mounted on the vessel: a duct positioned ahead of the propeller together with an integrated fin system within. The duct straightens and accelerates the hull’s wake into the propeller and also produces a net forward thrust. The fin system provides a pre-swirl to the ship’s...

Open the catalog to page 3

Save power The achievable power savings from the Becker Mewis Duct® are strongly dependent on the propeller thrust loading, from 3 % for multipurpose ships up to 8 % for tankers and bulk carriers. The power saving is virtually independent of ship draught and speed. The Becker Mewis Duct® is ideally suited to both newbuild and retrofit applications (e.g. tanker, bulker and MPC). Advantages • Fuel savings in average 6 % • Fuel savings up to 8 % in combination with a Becker Rudder • Reduction of NOX and CO2 emissions • Suitable for newbuildings and retrofits • Reduced vibrations and pressure...

Open the catalog to page 4

AS Valeria (Bulk Carrier) • Size: 57,000 dwt • Savings: 5.0% of fuel 1,002 t CO2 per year

Open the catalog to page 5

Combined principles Principles of energy savings Wake field equalisation The Becker Mewis Duct® straightens and accelerates the hull’s wake into the propeller and also produces a net forward thrust. Contra-rotating swirl Due to individually placed fins a pre-swirl in counter direction is generated, recovering the rotational energy from the slipstream. Reduction of propeller hub vortex An improved slipstream behind the duct significantly reduces the hub vortex with corresponding thrust deduction, leading to improved thrust and inflow to the rudder.

Open the catalog to page 6

Combined principles All three principles in one device Wake field equalisation Contrarotating swirl All in one – Becker Mewis Duct® The Becker Mewis Duct® combines all three of the previously mentioned principles in a non-linear interaction: The Becker Mewis Duct® harmonises and stabilises the flow and generates a pre-swirl to reduce the rotational losses in the propeller slipstream. The integrated fins have a stator effect by generating a pre-swirl in counter direction of the propeller operation. This generates more thrust. The fins are asymmetrically profiled and arranged to generate a...

Open the catalog to page 7

Samco Redwood (Crude Oil Carrier) • Size: 314,250 dwt • Savings: 6.4% of fuel 4,271 t CO2 per year

Open the catalog to page 8

Installation Newbuilding: The Becker Mewis Duct® installation can easily be done during the block stage of the stern boss with low effort for the shipyard and the owner. The yard is able to implement the installation into the production schedule. The Becker design team applies the interfaces of the Becker Mewis Duct® and the ship according to the ship’s steel structure and uses standard steel grades to build the Becker Mewis Duct®. The installation time is approx. four days. Retrofit: Becker designed the Becker Mewis Duct® to meet the challenges of a retrofit. The Becker Mewis Duct® can...

Open the catalog to page 9

Possible savings Possible savings with the Becker Mewis Duct® The curve below shows the dependence between the ship’s size and the gained power savings. It ranges from 3 % for multipurpose ships up to 8 % for tankers and bulk carriers. Bulk carrier Multipurpose vessel

Open the catalog to page 10

• Wake field equalisation • Reduction of propeller hub vortex • Contra-rotating swirl

Open the catalog to page 11

Case study Case study References The German Ahrenkiel Group updated its new 57,000 t bulk carrier AS Vincentia with a Becker Mewis Duct®. The vessel has a length of 189.99 m, a width of 32.26 m and a design draught of 11.30 m. The ship provided the unique opportunity to test the brand-new vessel with and without the Becker Mewis Duct® installed – with similar test parameters (sea/weather/ship condition). The sea trials confirmed the promising results of Becker’s CFD projections and the HSVA model test with actual fuel savings of around 5 %. The Ahrenkiel Group indicated their approval of...

Open the catalog to page 12

One of 16 possible Becker Mewis Duct® for Odfjell chemical tankers. • Size: 37,500 dwt per vessel • Savings: 5.0 % of fuel per vessel 1,187 t CO2 per year per vessel

Open the catalog to page 13

Rudder profiles Becker rudder profiles The combination of a Becker Mewis Duct® with a Becker Rudder can increase the energy savings dramatically, so that ships equipped with the Becker Bundle will significantly increase the ship’s propulsion efficiency. TLKSR® – Twisted Leading Edge Rudder • Higher propulsion efficiency with proven fuel savings • No rudder-induced cavitation erosion • No rudder horn required • Unlimited in size FLAP – Becker & Heracles Flap Rudders Becker Flap • Optimum balance and flap area • Minimum steering gear size • Easy maintenance of link and hinge system •...

Open the catalog to page 14

Rudder profiles NACA & MORE – Becker Full Spade Rudders • NACA: Economic alternative with proven NACA profile for applications with standard requirements. On request, special profiles such as NACA 63 or HSVA MP73 are available. • Becker Rudder designs: From Full Spade or heelsupported rudders for smaller and slower vessels to big vessels with KSR (King Support Rudder) or HERUS® support. BECKER NOZZLE • Increased bollard pull • Increased thrust • Better propulsion efficiency • Better steerage capacity • Reduced vibrations • Protection of propeller against damage • Reduced operation costs due...

Open the catalog to page 15All Becker Marine Systems catalogs and brochures

-

Energy-Saving Devices

2 Pages

-

LNG Hybrid Concepts

2 Pages

-

Becker Marine Products

19 Pages

-

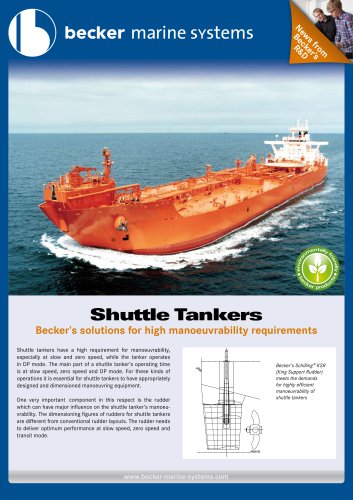

Shuttle tankers

2 Pages

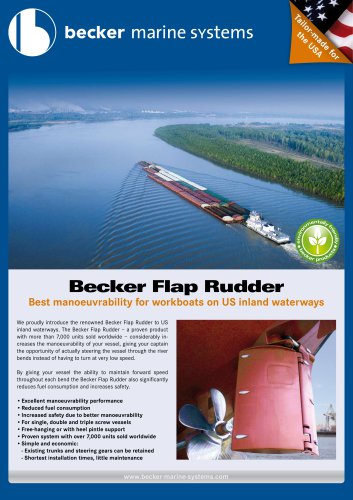

-

Becker Flap Rudder

2 Pages

-

Becker Bulb Rudders

4 Pages

-

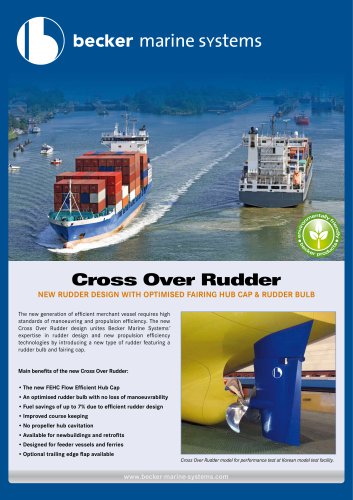

Becker Cross Over Rudder

2 Pages

-

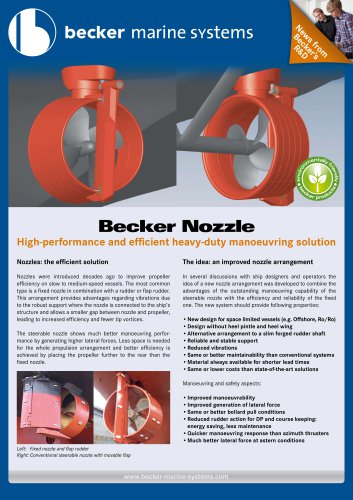

Becker Nozzle

2 Pages

-

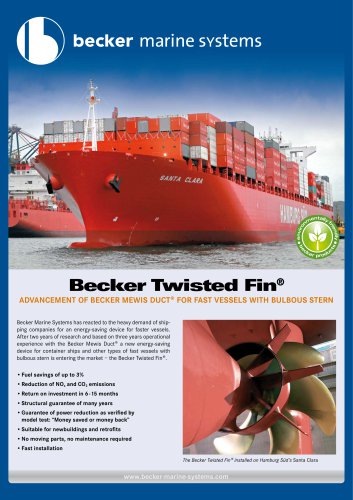

Becker Twisted Fin®

4 Pages

Archived catalogs

-

propeller nozzle for ships

4 Pages

-

flap rudder for ships

41 Pages