Catalog excerpts

GM-X Steel drain pipes and fittings ACO Marine, as a division of the internation- and fire protection systems. Specially ACO Marine's experience in this field is con- al ACO Group of companies with more than trained contacts in the ACO Marine sales firmed through certification from renowned 3600 employees worldwide, is now present- department, can provide complete support international test registers. ing new galvanized and coated steel pipe and discuss any special requirements and product ranges G MX and GMX-F for drainage bespoke designs. The collection and disposal of wastewater is demands (see behaviour in fire). The require- possible with GM-X steel pipes than with a decisive factor in shipbuilding, repair and ment for cost and weight saving can also be welded pipes or threaded pipes due to the conversion to ensure trouble-free operation. taken into account by the GM-X plug-in sock- reduced wall thickness. GM-X steel pipes meet the highest safety et system. A significantly lower weight is

Open the catalog to page 1

The GM-X socket is a two-stage design. The seal is retained by the first socket stage. The second stage centres the inserted pipe. The socket shape construction enables a solid, buckle-proof and rigid connection of pipes and mouldings to be made, and thus guarantees great tightness between the pipe and the socket, without the risk of the seal being compressed by its own or an out- side load. The GM-X seal is in the shape of a lip collar. It is inserted into the upper socket chamber. As a result of the other pipe end being pushed in, the sealing lips are forced against the inner wall of the...

Open the catalog to page 2

Corrosion proofing All pipes and fittings are hot galvanized is impact-resistant and shock-proof. The zinc coating produces a cathodic protection of the cut edges thus preventing bottom rust. In addition, the insides of the pipes and fit- tings are given an alkyd-melamine resin based plastic coating. A significant task falls upon the installer, who, in the final analysis, determines the practical value of a drainage installation. The superior quality of our pipe material and the first-class processing of our products help Drainage installations have to be able to be constructed without...

Open the catalog to page 3

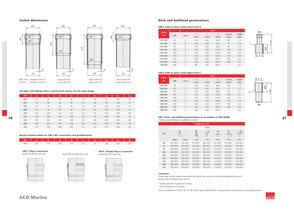

Production monitoring Quality management GM-X drain pipes and fittings are subject to production monitoring by monitoring by a certified institute. GM-X seals are also subject to production monitoring by a certified institute. GM-X drain pipes and fittings are subject to GM-X pipes and special fittings are certified by all leading test registers. This affirms their high operational safety. Deck and bulkhead penetrations CM-X socket flange without mating flange ANSI flange B 16.5 150 lb/sq.in CM-X spigot flange without mating flange ANSI flange B 16.5 150 lb/sq.in Vacuum installation in DN...

Open the catalog to page 4

For pipes and fittings with 2 sockets both sockets are the same design Special nominal widths for CM-X WC connections and préfabrication Socket DN 40-200 with seal Socket DN 250 with set of seal CM-X -VACplus Plug-in connection Socket DN 40-70 with seal Deck and bulkhead penetrations CM-X weld-on pieces with socket form E CM-X Deck- and bulkhead penetrations in accordance to DIN 86288 Following special fittings are available on request Please note, that all shaped components with bends may vary due to production-engineering reasons. Design data is available upon request. 11 welding area...

Open the catalog to page 5

Bends with small radius in acc. to EN 1123 form C2 Bends with small radius in acc. to EN 1123 form C2 Please note, that all shaped components with bends due to production-engineering reasons. Design data is available upon request. Vacuum installation in DN 40, DN 50, DN 70 with special GM-X-VACplus sealing element and standard x-socket piping system Connectors for changing from CM-X pipe to plastic pipe socket as per d10 plastic pipe diameter Connectors for changing from CM-X pipe to plastic pipe socket as per d10 plastic pipe diameter Vacuum installation in DN 40, DN 50, DN 70 with special...

Open the catalog to page 6

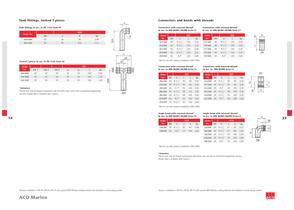

Tank fittings, forked T-pieces Tank fittings in acc. to EN 1123 form E5 Forked T-pieces in acc. to EN 1123 form E4 Please note, that all shaped components with the bend share varies due to production-engineering reasons. Design data is available upon request. Vacuum installation in DN 40, DN 50, DN 70 with special GM-X-VACplus sealing element and standard x-socket piping system Connectors and bends with threads Connectors with external thread* Connectors with internal thread* "Not for use with sanitary installations (DIN 1986). Connectors with external thread* Connectors with internal...

Open the catalog to page 7

Single branches in acc. to EN 1123 form Dl Red. single branches in acc. to EN 1123 form D11 Vacuum installation in DN 40, DN 50, DN 70 with special GM-X-VACplus sealing element and standard x-socket piping system Pipe bridges, drain traps Pipe bridges* in acc. to EN 1123 form C3 * Available with threaded plug drain on request. P-drain traps* in acc. to EN 1123 form CI * Available with threaded plug drain on request. S-drain traps* in acc. to EN 1123 form C2 * Available with threaded plug drain on request. Please note, that all shaped components with bends may vary due to...

Open the catalog to page 8

Double branches for corners in acc. to EN 1123 form D21 "Parts available only on request Red. double branches for corners in acc. to EN 1123 form D31 "Parts available only on request Transition branches in acc. to EN 1123 form Dl2 "Parts available only on request Vacuum installation in DN 40, DN 50, DN 70 with special GM-X-VACplus sealing element and standard x-socket piping system Connecting pieces Double sockets in acc. to EN 1123 Form F4 Push-in sockets with long socket in acc. to EN 1123 form F5 Repair coupling Vacuum installation in DN 40, DN 50, DN 70 with special GM-X-VACplus sealing...

Open the catalog to page 9

Cleaning pipes Cleaning pipes with round cleaning aperture Cleaning pipes with oblong cleaning aperture Clear width of cleaning aperture = 265 x 100 mm. Vacuum installation in DN 40, DN 50, DN 70 with special GM-X-VACplus sealing element and standard x-socket piping system Double branches in acc. to EN 1123 form D11 Red. double branches in acc. to EN 1123 form D21 "Parts available only on request Vacuum installation in DN 40, DN 50, DN 70 with special GM-X-VACplus sealing element and standard x-socket piping system

Open the catalog to page 10All ACO Marine catalogs and brochures

-

ACO Maripur NF data sheet

2 Pages

-

ACO Clarimar® MF

2 Pages

-

ACO Marine product catalogue

36 Pages

-

Clarimar MF 2016

2 Pages

-

Maripur NF 2016

2 Pages

-

ACO Marine River Cruise

4 Pages

-

ACO DataSheet PowerVAC

2 Pages

-

ACO Marine Water Maker WM3

2 Pages

-

Holland

1 Pages

-

Merchant vessel

1 Pages

-

Ferry

1 Pages

-

Cruise

1 Pages

-

160 m Megayacht

1 Pages

-

Pipe_system

14 Pages

-

1159_-image_marine_Hamburg

4 Pages

-

Stainless_Steel_Datasheet

8 Pages

-

ACO_Data_Sheet_Clarimar

2 Pages

Archived catalogs

-

ACO Marine Maripur

8 Pages