カタログの抜粋

Guide for ultrasonic leak detection in compressed air systems in an industrial environment

カタログの1ページ目を開く

Copyright 2014 by SDT International n.v. s.a. Second edition, English version. All rights reserved. Reproduction in any form of all or part of this document is not permitted without the written permission of: SDT International n.v. s.a. Bd. de l’Humanité 415, B – 1190 Brussels (BELGIUM) Tel: ++32.2.332.32.25 Fax: ++32.2.376.27.07 e-mail: info@sdt.be web page: http://www.sdt.eu

カタログの2ページ目を開く

SDT’s goal is to provide ultrasound solutions that give its customers a greater understanding about the health of their factory. SDT helps them predict failures, control energy costs and improve product quality while contributing to the overall uptime of their assets. It's know-how covers a wide range of applications: leak testing, detection of gaseous fluid leaks, monitoring of steam traps, monitoring of rotating machines and follow-up of their lubrication and the inspection of HV electrical equipment.

カタログの3ページ目を開く

1. Some data about compressed air 1.1 COMPRESSED AIR IS WIDELY USED AND ENERGY INTENSIVE Compressed air is easy to manufacture. Its production does not generate pollution or waste. It uses inexpensive and rugged components. It is easy to transport via cheap network of pipes. There is no risk in case of an accidental leak. These strong points explain why compressed air is the fourth most commonly used source of energy in industry, following electricity, natural gas and water. On average, it represents 13% of the industrial electricity consumption in France. However, its use is not without...

カタログの6ページ目を開く

This is about the thermodynamic efficiency. Actually, more than 90% of the electrical energy consumed is lost, notably in the form of heat. At best, 10% of this energy is converted into mechanical energy conveyed by the fluid. Routinely, the useful energy barely reaches 8%, especially when no campaign to search out leaks is in place. So you understand why compressed air so expensive. Overall performance of an optimised installation WHAT IS THE COST OF COMPRESSED AIR? While everyone knows the price per kWh of electricity, gas or water, few manufacturers are aware of the cost price of a cubic...

カタログの7ページ目を開く

WHAT IS THE COST OF A LEAK? Taking an average price of € 0.085/kWh over 8,700 hours of use per year, the table below gives a few examples of annual financial losses: Diameter (mm) Loss (€/year) Of course, these figures are multiplied by the number of leaks … LEAKS: AN UNACCEPTABLE WASTE Generally speaking, leaks impact on production and a health hazard. They colourless and usually industrial environments. do not have an do not represent are odourless, not audible in However, leaks represent 30-40% of compressed air production. And even more in some cases! They are very expensive and are...

カタログの8ページ目を開く

Average distribution of the compressed air consumption in industry THE ELIMINATION OF LEAKS IS AN ABSOLUTE PRIORITY The elimination of leaks is not the only way to optimise the cost of compressed air. The optimisation of production (control, variable speed and heat recovery) and processing (dryer, filters and condenser) must also not be overlooked. This action must be given top priority. The investment required is low. Just two hours are needed to become proficient in the use of an SDT device. Searching for leaks is relatively simple. Finally, the savings is substantial for an immediate...

カタログの9ページ目を開く

2. Detecting leaks by listening to the ultrasounds that they produce 2.1 LEAKS EMIT ULTRASOUNDS It is therefore vital to understand what ultrasounds are and how they relate to leaks in order to understand how to detect them properly. Sounds and ultrasounds are mechanical vibrations of matter. Ultrasound is the same type of vibration as sound but at a frequency higher than 20 kHz, which is inaudible to the human ear, which has a range of between 15Hz and 20Hz. Compared with the diffuse emission of sounds, ultrasounds spread in a concentrated fashion in one direction. They can be compared...

カタログの10ページ目を開く

The main function of the SDT detector is to convert high frequency signals into audible signals. It must be noted that the detector's central frequency band can be adjusted to a specific frequency between 15.1 and 190.7 kHz ; the default frequency is 38.4 kHz. The frequency bands are used depending on the type of sound to be detected. For the purposes of detection, an SDT detector is only sensitive to ultrasound vibrations. It restores the turbulence effects, i.e. the actual sound of the leak and it quantifies this leak in dBµV. THE ULTRASONIC SENSOR IS THUS THE BEST TOOL Searching for the...

カタログの11ページ目を開く

3. Detecting leaks with an SDT kit 3.1 SENSOR SELECTION GUIDE The sensor is selected based on two parameters: the distance to the equipment to be inspected and ease of access. Internal sensor Both the SDT200 and SDT270 detectors are equipped with an internal sensor. It is the ideal sensor when the areas to inspect are easily and directly accessible and located opposite the operator. Generally speaking, the sensor/inspection area distance is less than a meter. The precision indicator tip is particularly useful. Leak localisation becomes more precise when the sensor's detection window is...

カタログの12ページ目を開く

Acoustic cone or EDS (Extended Distance Sensor) The EDS screws onto the internal sensor. The acoustic cone has two properties that are particularly useful to the inspector: it increases the sensitivity of the internal sensor by 12 dB (*) and it is highly directional, meaning that it improves localisation of the leak compared to the internal sensor alone. (*) 12 dB means that the internal sensor equipped with the EDS is 4 times more sensitive. This substantial increase in sensitivity allows the operator to be up to 4 to 6 meters from the inspected area. Directivity allows you to accurately...

カタログの13ページ目を開く

Sensor selection guide depending on the distance and pneumatic density Less than 1m High density Internal sensor Flexible sensor Detecting the leak Begin by sweeping the area at mid-distance using the EDS or the parabolic sensor. Amplification set to maximum. Sweep from right to left and from bottom to top to locate the characteristic hissing sound of a leak. Search in the direction of the strongest signal to determine where the leak is coming from. For your comfort, the volume in the headphones can be increased or decreased using the left and right arrows. Detection is simple and intuitive...

カタログの14ページ目を開くSDT Ultrasound Solutionsのすべてのカタログとパンフレット

-

CONMONSense

2 ページ

-

Vigilant

2 ページ

-

ULTRAChecker

2 ページ

-

LEAKChecker

2 ページ

-

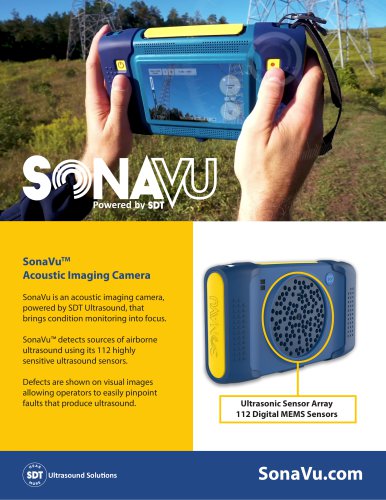

SonaVu

2 ページ

-

SHERLOG range

6 ページ

-

SDT200 Folder

2 ページ

-

T-Sonic1

2 ページ

-

HATCHecker

2 ページ

-

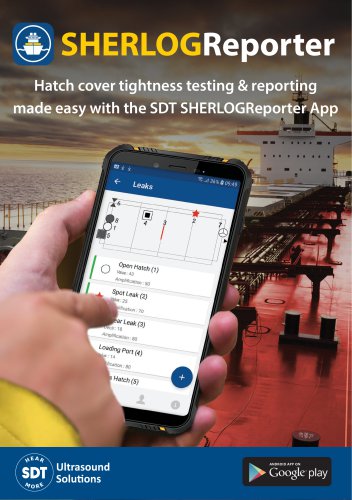

SHERLOGReporter

2 ページ

-

SDT340

4 ページ

-

SDT270 Folder

4 ページ