ウェブサイト:

Konecranes

ウェブサイト:

Konecranes

カタログの抜粋

INDUSTRIAL CRANES NUCLEAR CRANES PORT CRANES HEAVY-DUTY LIFT TRUCKS MACHINE TOOL SERVICE Lifting Businesses " Superior Crane Drive Technology

カタログの1ページ目を開く

Konecranes DynA Vector II dyna vector ii the superior crane drive technology The every-increasing safety, productivity and availability demands set new requirements on crane drive systems. These requirements cannot be fulfilled with general purpose inverters. That is why Konecranes has created DynA Technology with built-in safety and other cranespecific application features. We have strong experience not only in process crane applications, but also in cost-effective, light-duty cranes and harbor and shipyard crane projects. This gives us the core know-how to build the tailored drive...

カタログの2ページ目を開く

Developed in-house for crane use > Long-term experience in crane technology > Loaded with new features > More than an inverter > Options for all cranes > Suplified structure > Pre-tested solution > Smoother and more accurate starts/stops > Improved, optimized brake control > DynABus II > 24-hour product support > Comprehensive drive repair facilities on 3 continents > Stocking depot: Components and complete drives > Aftersales and technical support > Training

カタログの3ページ目を開く

Konecranes DynA Vector II worldwide experience in crane technology Crane-specific features Superior brake control ensures smooth and precise starts and stops > rake opening delay detection sequence B > agnetizing time detection sequence M > Optimized start delays due to advanced magnetizing and brake opening control > Closed loop zero-speed function and load floating ensures immediate response to repeated driving requests > Stop magnetizing allows big motors to restart faster > Closed loop brake slip supervision option Special feature > oad sway control L > LC/Profibus connection P >...

カタログの4ページ目を開く

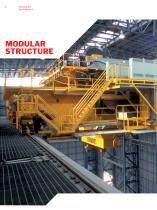

Konecranes DynA Vector II modular structure

カタログの6ページ目を開く

The control unit can be installed separately from the power module. The control unit has five extension board slots. The same control unit can be used with all sizes of inverters. The front cover of the control unit can be opened and the board connections are covered by the removable cover. The CPU board is included in the control unit. The Konecranes application software is loaded in the memory of the CPU board.

カタログの7ページ目を開く

Konecranes DynA Vector II Software features Software functions > Open loop V/f-control and flux vector speed control > Closed loop speed and torque control > Electronic motor potentiometer with 2 steps (AP) or 3 steps (EP3), analog voltage references from potentiometer (PO) or from radio (AU) and multistep speed references via digital inputs > Slow down and stop limitswitch both directions > Stopping method (Ramp/Brake) > Brake relay output > Thermistor input > Amount of digital inputs 11 > Extended Speed Range (ESR) > 2-hoist synchronizing > Simultaneous start control “Multicare” > 2-motor...

カタログの8ページ目を開く

dynareg & common dc-bus Redundancy > Decreases crane downtime > Modular design: Simplifies the lay-out of the electrical system No need for external braking resistor circuit > Braking resistors need maintenance > Braking resistor circuit is very vulnerable in some environments Makes standardization easier > With D2R it is possible to raise the DC-bus voltage level 10-25%, i.e. it is possible to use 500V motors with 400V supply Energy savings > Optimal power supply due to the sinusoidal load current > Consumes and returns clean, low harmonic power from the network > Handles more severe...

カタログの9ページ目を開く

Konecranes DynA Vector II hardware features Assembly and cubicle > Through-panel mounting for optimal dissipation of thermal power losses > Pre-designed mechanical construction for standard enclosures > Full range options for extreme environment conditions > Pre-designed optional redundancy system for additional reliability > Pre-engineered electrical room concept Main circuit designed for cranes > Accurate current feedback from all three phases > Brake chopper dimensioned for 100% duty > Sophisticated intermediate circuit charging > Latest semiconductor technology > Built-in filter...

カタログの10ページ目を開く

AFteRSALES SUPPORT Fulfilled safety and EMC standards Safety > D2C/D2H fulfill the safety requirements defined in the standards EN 50178 and EN/IEC 60204-32 LV and EMC directives > Conforms to the relevant safety provisions of the Low Voltage Directive (2006/95/EC) and EMC Directive (2004/108/EC) Immunity > D2C/D2H fulfill the immunity requirements defined in the EN/IEC 61800-3: 2004 for the second environment. EN 61000-6-1 (residential, commercial and light industry) and EN 61000-6-2 (industrial environment) Emissions > D2C/D2H fulfill the emission requirements of the EN/IEC 61800-3: 2004...

カタログの11ページ目を開く

Nuclear Cranes Port Cranes Heavy-duty Service Lift Trucks Machine Tool Service Konecranes is a world-leading group of Lifting Businesses™ offering lifting equipment and services that improve productivity in a wide variety of industries. The company is listed on NASDAQ OMX Helsinki Ltd (symbol: KCR1V). With over 10,000 employees at more than 570 locations in almost 50 countries we have the resources, technology and determination to deliver on the promise of Lifting Businesses™. © 2011 Konecranes. All rights reserved. ‘Konecranes’, ‘Lifting Businesses’ and are registered trademarks of...

カタログの12ページ目を開くKonecranesのすべてのカタログとパンフレット

-

RTG RETROFITS

28 ページ

-

BIG IN BRAZIL

2 ページ

-

YOUR WAVE OF SUCCESS

11 ページ

-

RIGHT ON TRACK

11 ページ

-

Straddle carrier

22 ページ

-

Konecranes ARTG brochure

12 ページ

-

RailQ Runway Survey

4 ページ

-

Smarter CXT Cranes

8 ページ

-

Steel industry offering

20 ページ

-

Steel Melt Shop Cranes

12 ページ

-

Sway Control

4 ページ

-

Shipyard Cranes

16 ページ

-

Munckloader Cranes

8 ページ

-

Hevi-Lift Hoists

3 ページ

-

CXT Biomass Crane

12 ページ

-

CXT Compact

6 ページ

-

Automated RTG

12 ページ

-

RTG

2 ページ

-

RMG

4 ページ

-

Shipyard crane

6 ページ

-

AGD

6 ページ

-

Box runner

20 ページ

-

STS

2 ページ

カタログアーカイブ

-

CONTAINER LIFT TRUCKS

12 ページ

-

REACH STACKER

12 ページ

-

KONECRANES

8 ページ