ウェブサイト:

GH Cranes & Components

ウェブサイト:

GH Cranes & Components

グループ: Industrias Electromecánicas GH, S.A

カタログの抜粋

Advanced Control and Monitoring GH’S SOLUTION: COREBOX: Control + Monitoring + Connectivity*. / Control: • Electronic load limiter linked to a load cell. • Controls hoist motor in the event of an over-temperature occurrence. / Monitoring: • Operational data: Times, Moves, Cycles, Loads Lifted. • Incident log: Overloads, Over-Temperature, VFD (variable speed drive) faults. • Remaining DWP (Design Working Period, calculated according to ISO 12482). It is reported as SWP (Safe Working Period). / Connectivity*: • Communicates the monitored parameters via a cellular network to GH CRANES’s proprietary data platform. GH CRANES uses this information to provide its customers with , a set of advanced usage and maintenance services • Using the CUSTOMER PORTAL of GH CRANES (portal.ghcranes.com), the crane’s owner can access complete and real-time information on the crane’s operation. / All functions (Control + Monitoring + Connectivity*) integrated into a single device. / Available connectivity to accessories, such as Displays and Radio Controls, for continuous viewing of data such as Lifted Loads and Safe Working Period (SWP). / By communicating via 3G/4G** networks, COREBOX does not interfere with the customer’s internal network. / COREBOX may be retrofitted to other crane brands, enabling monitoring and SWP calculation, without interfering with their operation. 1 COREBOX receives data from the load cell, the VFD’s, and the thermal sensors of the motors. 2 COREBOX process and records the operating parameters of the crane and the errors detected. 3 COREBOX sends the data of the lifted load and SWP to the display or radio control. 4* COREBOX communicates via the cellular network, to GH CRANES’* proprietary platform* TECHNICAL DETAILS Power supply 48-220Vac. Analog load cell input. Voltage inputs for movements with 48-220Vac range. Outputs to relay with possibility of timing. Input for motor over-temperature sensor. Optimized for Schneider variable frequency drives and Danfoss-Ikusi and Autec radio controls. * Connectivity is optional and involves additional cost. ** Connectivity is structured to match locally available 3G or 4G networks. GH Cranes continually improves its products and therefore reserves the right to modify this document

カタログの1ページ目を開くGH Cranes & Componentsのすべてのカタログとパンフレット

-

GH Real Time

2 ページ

-

GH catalog accessories

114 ページ

-

INDUSTRIAL SOLUTIONS

14 ページ

-

GH Corporate catalog

87 ページ

-

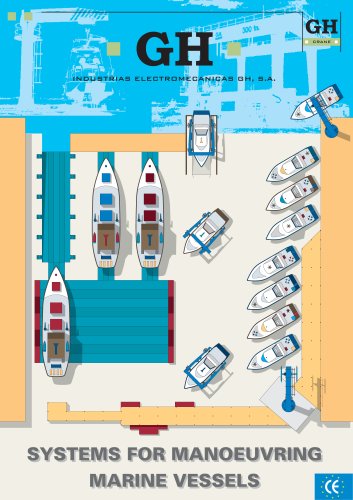

MARINE SOLUTIONS

14 ページ

-

Sell sheet GHE17

2 ページ

-

STANDARD CRANES

32 ページ

-

ATV+AntiSway

1 ページ

-

Transfer carts

8 ページ

-

GH´NEWS 22

28 ページ

-

Open winch

12 ページ

-

End carriages

8 ページ

-

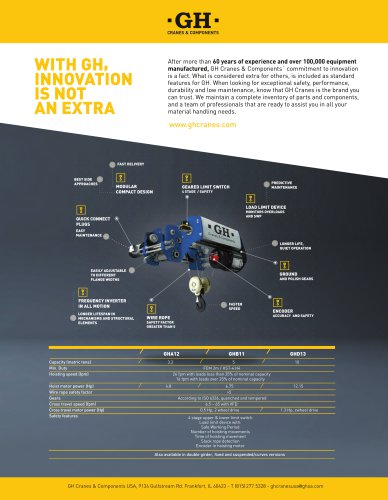

Components

12 ページ

-

Waste-to-Energy cranes

12 ページ

-

GHE17

2 ページ

-

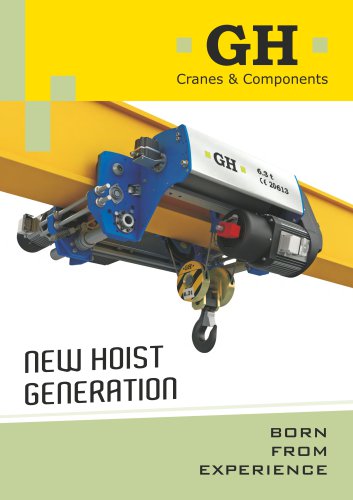

High capacity hoists

8 ページ

-

GH Motion

18 ページ

-

GH´NEWS 21

32 ページ

-

GH´NEWS 20

28 ページ

-

GH´NEWS 19

71 ページ

-

GH´NEWS 18

11 ページ

-

GH´NEWS 17

5 ページ

-

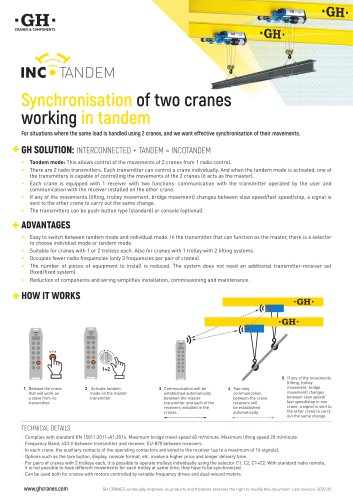

Coreplus Synchro

1 ページ

-

Coreplus Stability

1 ページ

-

Lifting your world

24 ページ

-

Mailing kits

2 ページ

-

Gantry cranes

12 ページ

-

Automotive

16 ページ

-

Aeronautic

16 ページ

-

Pulp and paper industry

12 ページ

-

Shipyard cranes

20 ページ

-

Jib cranes

8 ページ

カタログアーカイブ

-

Ponts roulants

13 ページ

-

Gantry cranes

12 ページ

-

Bridge cranes

12 ページ

-

Bridge cranes

12 ページ

-

Hoists

8 ページ