ウェブサイト:

GH Cranes & Components

ウェブサイト:

GH Cranes & Components

グループ: Industrias Electromecánicas GH, S.A

カタログの抜粋

BRAKE Continuous monitoring of the lifting brake • • • • • THE GH SOLUTION: BRAKE MONITORING The brake status (released-applied) is monitored, to ensure correct synchronisation of the brake and lifting motor. The lifting motor is stopped if the brake has not been released correctly. Brake pad wear is monitored, checking its correct condition. Simple solution with no need for adjustments. Easy retrofitting of hoist to incorporate these safety functions. Increased safety and durability of GH hoists. Prevents motor problems when the motor is operated when the brake has not been released. Prevents dropping of loads due to brake contactor malfunctioning. Prevents risky situations by actively detecting brake pad wear. Single sensor solution for both functions. Direct measurement, avoiding interpretation errors. A sensor is integrated in the lifting brake, which carries out the 2 functions: // A. Brake monitoring function - At the start of the lifting manoeuvre, if the sensor gets no return from the brake in less than 100ms, the motor is de-energised and the manoeuvre is stopped. - At the end of the lifting manoeuvre, if the sensor gets no return from the brake in less than 100ms, the brake is de-energised, guaranteeing the mechanical actuation of the brake. // B. Wear monitoring function - The thickness of the brake pad is continuously monitored. - If the wear threshold is reached, the sensor triggers a signal, the brake is mechanically applied, and the crane is stopped. - Optional: Brake wear warning signal. The signal activates the light corresponding to brake wear to warn the user. TECHNICAL DETAILS The brake release and brake pad wear monitoring functions are carried out by means of a mechanical 2-contact sensor: - Brake status contact: brake released – brake applied. - Brake pad status contact: brake pad OK – brake pad worn. The measurement is a direct measurement of the position of the brake pad in relation to the brake holder. The sensor is not affected by the temperature or magnetic fields. The activation – deactivation distances of all positions are fixed (factory preset), and cannot be changed. GH Cranes continually improves its products and therefore reserves the right to modify this documen

カタログの1ページ目を開くGH Cranes & Componentsのすべてのカタログとパンフレット

-

GH Real Time

2 ページ

-

GH catalog accessories

114 ページ

-

INDUSTRIAL SOLUTIONS

14 ページ

-

GH Corporate catalog

87 ページ

-

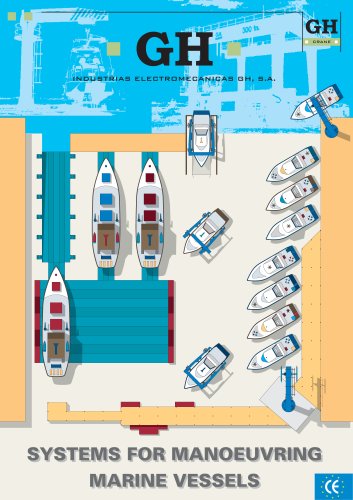

MARINE SOLUTIONS

14 ページ

-

Sell sheet GHE17

2 ページ

-

STANDARD CRANES

32 ページ

-

ATV+AntiSway

1 ページ

-

Transfer carts

8 ページ

-

GH´NEWS 22

28 ページ

-

Open winch

12 ページ

-

End carriages

8 ページ

-

Components

12 ページ

-

Waste-to-Energy cranes

12 ページ

-

GHE17

2 ページ

-

High capacity hoists

8 ページ

-

Corebox

1 ページ

-

GH Motion

18 ページ

-

GH´NEWS 21

32 ページ

-

GH´NEWS 20

28 ページ

-

GH´NEWS 19

71 ページ

-

GH´NEWS 18

11 ページ

-

GH´NEWS 17

5 ページ

-

Coreplus Synchro

1 ページ

-

Coreplus Stability

1 ページ

-

Lifting your world

24 ページ

-

Mailing kits

2 ページ

-

Gantry cranes

12 ページ

-

Automotive

16 ページ

-

Aeronautic

16 ページ

-

Pulp and paper industry

12 ページ

-

Shipyard cranes

20 ページ

-

Jib cranes

8 ページ

カタログアーカイブ

-

Ponts roulants

13 ページ

-

Gantry cranes

12 ページ

-

Bridge cranes

12 ページ

-

Bridge cranes

12 ページ

-

Hoists

8 ページ