Website:

Xylem

Website:

Xylem

Group: ITT Industries

Catalog excerpts

11 Flexible Impeller Pumps MODEL NUMBER FLOW PATTERN/ CONNECTION FLANGE MOUNT

Open the catalog to page 1

PALMER LEHMAN Selection Guide Flexible Impeller Pumps

Open the catalog to page 2

11 Flexible Impeller PumpsSELECTION GUIDE MODEL NUMBER FLOW PATTERN/ CONNECTION FLANGE MOUNT

Open the catalog to page 3

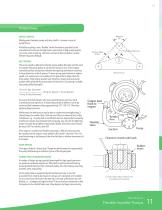

11 Flexible Impeller Pumps INTRODUCTION Jabsco Original Flexible Impeller Pumps — Pedestal, Clutch & Engine Cooling HOW IT WORKS Flexible vanes create increased volume when leaving the eccentric cam creating a vacuum, and thus drawing in liquid, instantly priming the pump. As the flexible vanes rotate, the liquid is carried through the pump from the inlet to outlet port, each successive vane drawing in liquid. When the flexible vanes again contact the eccentric cam they bend with a squeezing action which provides a continuous, uniform discharge of liquid.

Open the catalog to page 5

FEATURES • Versatile: The flexible impeller pump combines the priming feature of positive displacement type pumps with the general transfer ability of centrifugals. It will pump either thin or viscous liquids and can handle more solids in suspension than other types of rotary pumps. It operates at low or high speeds, can be mounted at any angle and pumps in either direction with equal efficiency. • Self-Priming: Pumps instantly with dry suction, lifts up to 10' (3m) — up to 25' (8m) when wetted. Permits cleaner, safer installations. No foot valve required. • Simplicity: One moving part — a...

Open the catalog to page 6

11 Flexible Impeller Pumps INTRODUCTION Keel Cooling In principle, this is similar to a heat exchanger cooled system, but the raw water circuit and heat exchanger have been replaced by pipes attached externally to the vessel’s keel. Pipe bore and surface area must be adequate for effective dissipation of heat from the primary circuit to sea or river water. In some installations where the flow capacity of the centrifugal circulating pump is insufficient due to system pressure losses through keel pipes, cylinder block and exhaust manifold, a Jabsco pump may be used (flow capacity...

Open the catalog to page 7

Safety Margins The raw water flow capacities indicated earlier are for diesel engine cooling systems and include a safety margin of some 30% to ensure adequate engine cooling under adverse operating conditions. As gasoline engines, unlike diesel engines, have a high heat rejection rate at idling speed, an increase in pump flow capacity of some 10% at maximum rpm is recommended. While flow capacities can be affected by salt deposits or scale in pipes due to operation in tropical regions, seawater pollution or age and wear of pumps and systems in general, this is usually a gradual process...

Open the catalog to page 8

11 Flexible Impeller Pumps INTRODUCTION Pump Selection Most proprietary marine engines are already fitted with specially adapted flange mounted Jabsco cooling pumps driven by gears or couplings of various descriptions. DIESEL ENGINES Heat exchanger cooling 18 GPM (68 LPM) — raw water GASOLINE ENGINES Increase diesel engine figures by about 10%. A belt drive from the crankshaft pulley will enable almost any standard foot mounted bronze Jabsco pump to be selected, provided that the required cooling flow rate is obtained without operating the pump at excessive speeds. Keel cooling 36 GPM (136...

Open the catalog to page 9

Pump Drives DIRECT DRIVES Misalignment between pump and drive shaft is a common cause of pump failure. A flexible coupling is only “flexible” within limitations specified by the manufacturer. Excessive misalignment, particularly at high pump speeds, can cause noise, knocking, vibration, premature bearing failure, usually followed by pump leakage. BELT DRIVES The pump speed is determined by the engine pulley diameter and the need to maintain the pump pulley at a practical maximum size. Some engine crankshaft pulleys incorporate vibration dampening membranes resulting in large diameters at...

Open the catalog to page 10

11 Flexible Impeller Pumps PULLEY DRIVEN PUMPS Jabsco pumps have serviced major engine builders globally for more than 70 years. The self-priming flexible impeller pump is the industry recognized technology standard for leisure and work boat engine cooling. Being an original Jabsco, you are assured the highest grade bronze and stainless steels are used in keeping your engine at peak operating temperature. Operating in either direction, with flows up to 83 GPM (314 LPM) and multiple port configurations, flexible impeller pumps are ideally suited to washdown, circulation and fire duty...

Open the catalog to page 11

• Two single row ball bearings. • Two single row ball bearings. • Self-priming up to 10' (3m) vertical lift. • Self-priming up to 10' (3m) vertical lift. 5-15/16" long x 3-1/2" wide x 3-5/16" high (15.1cm x 8.9cm x 8.4cm) 4-7/16" long x 4-1/8" wide x 3-13/16" high (11.3cm x 10.5cm x 9.7cm) Pump with neoprene impeller, full cam, lip seal Pump with neoprene impeller, full cam, lip seal Pump with nitrile impeller, full cam, lip seal • Mechanical face seal. • Mechanical face seal. • Double row ball bearing. • Double row ball bearing. • Self-priming up to 10' (3m) vertical lift. • Self-priming...

Open the catalog to page 12

11 Flexible Impeller Pumps PULLEY DRIVEN PUMPS Original Jabsco Flexible Impeller Pumps are available with neoprene impellers for water (45-160°F, 8-70°C) and general purpose pumping and nitrile impellers which are ideal for oil-based products (50-160°F, 10-82°C). Head pressures up to 26 psi or 60'. can be accommodated. For reduced flow, choose the half cam version. The choice of a mechanical seal extends pump life. Do not pump gasoline or other flammable liquids. Do not run dry. For service and spare parts see pages 162-217. Quoted flows at 10' (3m) head and 1750 rpm. • 23 GPM (87 LPM). •...

Open the catalog to page 13

Original Jabsco Flexible Impeller Pumps for commercial duty are fitted with proven quality mechanical seals, providing long life under exacting conditions. Bearings are spaced to allow higher speeds, without jeopardizing life, and the open design allows debris to pass through the pump without affecting flow or reliability. All Jabsco pumps are easily maintained using ordinary hand tools. For service and spare parts see pages 162-217. Quoted flows at 10' (3m) head and 1500 rpm. • Self-priming up to 18' (5.5m) vertical lift. • Self-priming up to 15' (4.5m) vertical lift. • Special design for...

Open the catalog to page 14All Xylem catalogs and brochures

-

23680 Technical Data Sheet

2 Pages

-

23610 Technical Datasheet

2 Pages

-

18670 Technical Datasheet

4 Pages

-

18660 Technical Datasheet

4 Pages

-

18220 Promotional Datasheet

2 Pages

-

General_Industrial_Catalo

24 Pages

-

Jabsco Marine Toilets

16 Pages

-

Oil_Change_Diesel

6 Pages

-

Marine Product Catalog

7 Pages

-

Additional Information 11

4 Pages

-

Chemical Resistance Guide 10

6 Pages

-

Specialty Products 09

6 Pages

-

Sliding Vane Pumps 08

2 Pages

-

Oscillating Pumps 07

2 Pages

-

Rotary Lobe Pumps 06

3 Pages

-

Industrial Pumps Catalogue

94 Pages

-

FLOJET Beverage Run Rise Charts

10 Pages

-

Washdown Pumps

2 Pages

-

Water Pressure Systems

10 Pages

-

Toilet Systems

14 Pages

-

Livewell/Baitwell Pumps

6 Pages

-

Bilge Pumping Systems

24 Pages

-

Aerogen Wind Generator

3 Pages

-

Speciality Products

5 Pages

-

Sliding Vane Pumps

5 Pages

-

Oscillating Pumps

2 Pages

-

Rotary Lobe Pumps

3 Pages

-

Hand Pumps

2 Pages

-

Gear Pumps

2 Pages

-

Diaphragm Pumps

15 Pages

-

Centrifugal Pumps

19 Pages

-

MODEL 34754-0000

2 Pages

-

MODEL 34744-0000

2 Pages

-

4125 SERIES

4 Pages

-

4105 series

4 Pages

-

2760-SERIES

2 Pages

-

Exploded View

2 Pages

-

Impeller Replacement

10 Pages

-

Searchlights

8 Pages

-

Ventilation Blowers

4 Pages

-

General Purpose Pumps

8 Pages

-

Oil Change & Diesel

6 Pages

-

Washdown Pumps

2 Pages

-

Water Pressure Systems

10 Pages

-

Livewell/Baitwell Pumps

6 Pages

-

Toilet Systems

12 Pages

Archived catalogs

-

Bilge Pumping Systems

26 Pages

-

Service Parts

80 Pages

-

Impeller Replacement

16 Pages

-

Searchlights

12 Pages

-

Oil Change & Diesel

10 Pages

-

FLOJET BevJet

12 Pages

-

General Purpose Pumps

14 Pages

-

OVERVIEW OF PARTS

2 Pages

-

Flexible Impeller Pumps

40 Pages

-

59000_aqua_filta_promo

2 Pages

-

Type III MSD Waste

18 Pages

-

52600 Series

18 Pages

-

SELF-PRIMING

4 Pages

-

VENTED LOOP SOLENOID

1 Pages

-

233SL Dual Beam Searchlight

2 Pages

-

MINI ACCUMULATOR TANK

2 Pages

-

Par-Max Series

2 Pages

-

Jabsco

2 Pages

-

Marine Product Guide

24 Pages

-

Brochure

4 Pages