Website:

Mac GREGOR

Website:

Mac GREGOR

Group: Cargotec

Catalog excerpts

TECHNICAL INFORMATION Planning the MacGregor hoistable deck Our aim is to design hoistable decks which are efficient, economic and safe, while fully meeting the specific operating requirements. The more information that can be given on these prerequisites, the greater the chance to find the optimum solution. Under the following headings information requirements can found before commencing the project. If these answers are available at the earliest stage possible, work will be saved during the later stages, gaining valuable time by shortening the lead time between initial contact and delivery. We define hoistable decks as any type of non-integrated decks that can be quickly moved to alternative working levels and stowed beneath the deckhead when not in use. Decks that are height-adjusted by a mobile deck lifter, are also called liftable decks. Hoistable decks consists of a number of panels that can be separately operated. This system makes it possible to efficiently stow vehicles with different headroom requirements. In order to establish the configuration of the hoistable deck we need to know the following data. Size of the hoistable deck What is the total required useful area for vehicle loading? How many deck levels are needed between the integrated decks? Shall the deck cover the full width between bulkheads or steel structure boundaries, or just a part of it? This is common on ferries where one lane is reserved for higher vehicles, such as lorries and coaches. Panel arrangement and size We need drawings of the ship to investigate the hull restrictions. It could be the location of support pillars, girders and bulkheads or any other item that may influence the function of the deck, such as personnel access doors, sloping decks etc. In those areas panels may be supported or divided. For decks partly covering the width we require the minimum clear width. A normal value is 2,2 m for each car lane plus 0,6 m. With mobile deck lifter operation the size of the panels will be restricted to maximum around 14x14 m to avoid excessive deflection. If you require two levels of hoistable decks the size of the panels may be further restricted, because the total lifting capacity of the scissors lift is about 40 tonnes. Access ramp How many access ramps are needed for each level of hoistable car decks? Indicate where they should be placed to optimise the cargo flow. Should the access be from the integral deck below or from a fixed ramp? To establish the length, width and other data of the ramp please study our datasheet Hoistable ramps. In RoRo passenger ships the width of the ramp is equal to the width of the panels, so the cars can be driven straight on and off the panels to meet the demands for swift loading and unloading. Clear height What is the required clear headroom on each working level? Furthermore, what is the clear height below the hoistable decks in stowed position? Loadings In order to dimension the steel structure with the required strength and minimum weight we need to know the following: What kind of vehicles will be loaded? What are the axle loading and wheel print area? How many axles are there and what is the distance between them? What is the maximum uniformly distributed loading on the panels? We will also include the ship's acceleration factors at sea in our calculations, if these are known.

Open the catalog to page 1

Interface between hoistable deck and ship The operating and securing equipment is never allowed to intrude into the cargo space. The operating equipment is either located in the deck panel or in the hull between girders or in the deck head. It is important that you reserve space for the decks in stowed position. A thickness of approximately 300-450 mm for each level of decks is required, depending on the size of and loading on the largest panel. Also reserve space for the operating equipment for the access ramp. Operating system capacity The determinating factors in dimensioning the...

Open the catalog to page 2

Jigger-winch mounted in the side shell structure Pulling cylinder/electrical winch in the panel Working position Stowed position Stowed position Car lashing options The most cost-effective solution is 45–60 mm holes in the top plate, but it can only be used on the open web steel structure with steel top plate. Plywood top solutions use stiffeners with holes in the top flange. The plywood is supported on the stiffeners, thereby avoiding lashing holes in the plywood top. Handrails Sockets for handrails are provided at each joint between the panels and a number of stanchions and guard rope are...

Open the catalog to page 3

Guiding and supporting options At least two corners of each deck panel must be connected to pillars or bulkheads, where guides and support pads can be fitted. The support pads transmit the lateral forces when the deck is carrying cargo. The guides are guiding the panels during lifting and lowering but they also transmit the horizontal forces from the sea. The free corners of the panels are supported by foldable support links. When there is only one working level all support pads are fixed and the support links are not adjustable. For configurations with alternative working levels the...

Open the catalog to page 4All Mac GREGOR catalogs and brochures

-

MacGregor gravity systems

2 Pages

-

RoRo conversions

7 Pages

-

Hoistable decks

4 Pages

-

GLE crane

2 Pages

-

K4 crane

2 Pages

-

Lattice Boom Crane

4 Pages

-

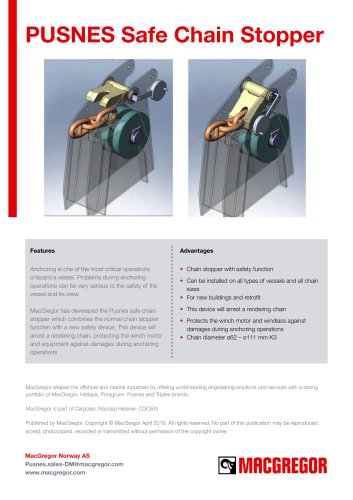

PUSNES Safe Chain Stopper

1 Pages

-

Side, stern and front doors

4 Pages

-

Cargo HandlingBook

116 Pages

-

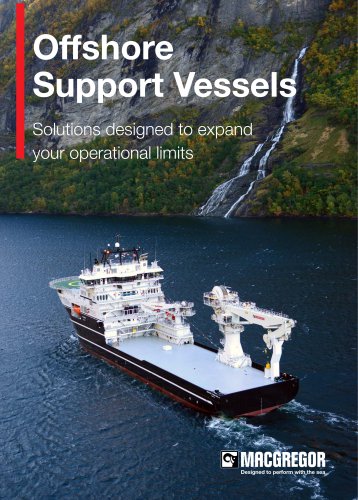

Offshore Support Vessels

20 Pages

-

Rescue and work-boat davits

8 Pages

-

Mooring andauto-mooring

7 Pages

-

Hoistable ramps

4 Pages

-

Straight stern ramps

4 Pages

-

Telescopic marine crane

4 Pages

-

Knuckle jib marine crane

4 Pages

-

Steering gear

2 Pages

-

GL crane

2 Pages

-

Cranes for all ship types

8 Pages

-

Cargo Handling Book

116 Pages

-

Selfunloader Services

8 Pages

-

K4 crane

2 Pages

-

HH crane

1 Pages

-

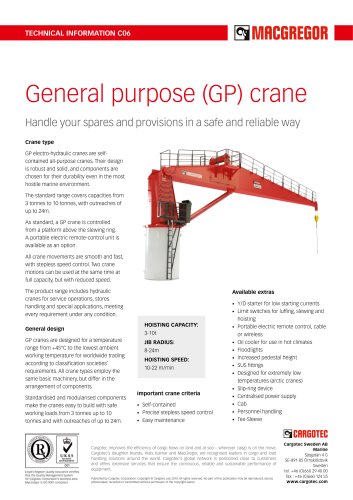

GP crane

1 Pages

-

GLH crane

2 Pages

-

GLE crane

2 Pages

-

GLB crane

2 Pages

-

GL crane

2 Pages

-

Electric crane

4 Pages

-

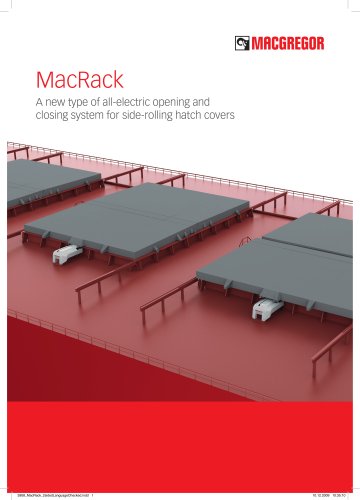

Mac Rack

2 Pages

-

MOOREX

8 Pages

-

Conversion

12 Pages

-

H2 Folding

8 Pages

-

Shortsea vessels

8 Pages

-

RoPax ferries

8 Pages

-

Land Port

8 Pages

-

Electric drive

4 Pages

-

Deepsea RoRo vessels

12 Pages