Website:

HYUNDAI HEAVY INDUSTRIES

Website:

HYUNDAI HEAVY INDUSTRIES

Group: Koshipa

Catalog excerpts

HEAVY INDUSTRIES CO.,LTD. OFFSHORE & ENGINEERING 1, Jeonha-dong, Dong-gu, Ulsan, Korea E-mail: obdb@hhi.co.kr Building a better future- Global Leader HEAVY INDUSTRIES CO.,LTD.

Open the catalog to page 1

Hyundai Heavy Industries Creating a Better Future ORGANIZATION MESSAGE BUSINESS AREA OTHER DIVISIONS FPSO LAND-BASED MODULE FABRICATION SEMI-SUBMERSIBLE UNIT JACK-UP PRODUCTION DRILLING & QUARTERS TOPSIDE MODULE & LIVING QUARTERS SUBSTRUCTURE ON-GROUND SHIPBUILDING OFFSHORE INSTALLATION HOOK-UP & COMMISSIONING CONSTRUCTION OF ONSHORE PROCESS PLANT MARINE TERMINAL AND JETTY your expectations DESIGN & ENGINEERING RESEARCH & DEVELOPMENT QUALITY MANAGEMENT HSE MANAGEMENT AMENITIES PERFORMANCE RECORD GLOBAL NETWORK

Open the catalog to page 2

Who we are The Offshore & Engineering Division of HHI covers Engineering, Procurement, Construction, Offshore Installation and Project Management for all kinds of offshore oil and gas facilities. By combining the best yard facilities in the world with the creative talents of our employees, we persistently improve our capability to meet future challenges in the offshore oil and gas industry.

Open the catalog to page 3

Hyundai Heavy Industries Shipbuilding Division Offshore & Engineering In the Past (1976 - 1990) Business Development & Marketing Industrial Plant & Engineering Project Management Division Design & Engineering Engine & Machinery Division Procurement Electro Electric Systems Division Construction Equipment Fabrication & Construction Offshore Installation Division Hook-up & Commissioning Research & Development Administration & Assistance Seoul & Overseas Offices Quality Management Starting from fabrication of small size offshore platforms, Offshore & Engineering Division of HHI has grown as a...

Open the catalog to page 4

what you want Since 1976, HHI has focused on continually improving its ability to design, construct, install and commission offshore projects on an EPCI basis. Today, our experience ranges from conventional platform and pipeline field developments to state-of-the-art FPSO projects. Our motto is to design facilities that our client really desire. We strive to develop the means to effectively build, deliver and commission the project. Business Area As a leading EPCI contractor for offshore oil and gas projects, primary business areas of HHI Offshore Yard include all phases of project...

Open the catalog to page 5

HHI Major Construction Equipment Super-Gantry Cranes HHI's offshore main yard is located at Ulsan Port, which is 7 km away from its main complex in Ulsan, Korea. The yard spreads over 258 acres of paved area having world-class construction facilities. The shops and spaces in its main complex are also utilized for the offshore works. HHI built a new drydock in its offshore yard in february 2009. The new drydock was built for building large size offshore floating facilities including FPSO, FPU, Semi... even large size of LNG FPSO. No.of Units Offshore Yard Crawler Cranes Hydraulic...

Open the catalog to page 6

FPSO Floating Production Storage & Off-Loading The recent emphasis in offshore deepwater projects has led to an increased demand for floating production systems such as FPSOs, FSOs, FPUs, PDQs, etc. HHI has entered the FPSO market since 1996 with two EPC contracts from Petrobras for the conversion of P-33 & P-35 FPSOs. Given the successful on-time delivery of the P-33 & P-35 FPSOs, the MPG consortium awarded HHI a contract for the fabrication of the Girassol FPSO for Total in the Block 17 field offshore Angola with over 2 million barrels of oil storage and production rate of 250,000 bopd....

Open the catalog to page 7

FPSO Floating Production Storage & Off-Loading Land-Based Module Fabrication The natural gas demand will steadily increase in line with clean energy policy all over the world. There are many planed oil & gas treatment facilities including LNG development projects and opportunities for HHI, Hyundai Heavy Industries, to participate in such projects, especially land-based module fabrication and plan to expand HHI’s business area taking into account of HHI’s Yard capacity and abundant other related oil and gas platforms & FPSO projects experiences. With its well-qualified experts and...

Open the catalog to page 8

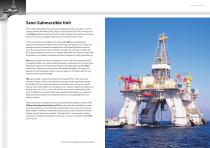

Semi-Submersible Unit Semi-submersible drilling rigs have been traditionally built in a drydock. However, starting with the BP Harding PDQ project in 1993 and the Troll C FPU hull project in 1998, HHI developed construction methods that will allow these hull-type structures to be built on land, and safely loaded onto a dock-side transport vessel. For the construction of a drilling semi-submersible, HHI has developed one additional construction method known as the Super-Lift operation. The Super-Lift operation involves building the complete deck of the floating facility at ground level....

Open the catalog to page 9

Topside Super-Lifting Registered in the Guinness Book Offshore & Engineering Division has developed unique technology for constructing large offshore structures on the yard instead of in a drydock. HHI's so-called "On-ground Build" method has been verified by oil majors through the construction of Semi-submersible rigs, Jack-up rigs, FSO and other huge offshore facilities. Furthermore, HHI lifted the 12,112 ton topsides for Na Kika FPU project ordered by Shell, and HHI's innovative lifting technique, Super-Lift, was registered in the Guinness Book of World Records in 2002. A portfolio! the...

Open the catalog to page 10

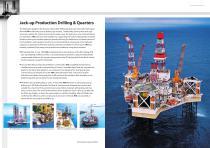

Jack-up Production Drilling & Quarters The fabrication programs for the semi-submersible drilling rigs built upon the earlier techniques allowed HHI to fabricate jack-up drilling rigs onshore. Traditionally, moving these hull-type structures outside the marine environment would cause the hulls to be over-stressed during the operations. HHI overcame this limitation by supporting the hull on hydraulically activated skidshoes during the loadout operation, thereby allowing the deflections and deformations of the foundations and transport vessel to be accommodated by movements in the hydraulic...

Open the catalog to page 11

AGIP, Sabratha Platform VEBA, Hanze F2A Integrated Production Deck (IPD) HMDC, Hibernia Process & Quarters Modules WOODSIDE, Goodwyn-A Process Platform KNOC, RongDoi Platform ADMA OPCO, Umm Shaif Platform Phillips, Bayu Undan DPP/CUQ Topside Topside Module & Living Quarters Since the first Champion-7 gas compression module was fabricated for Brunei Shell Petroleum in 1980, more than 400 topside modules and living quarters have been fabricated at the HHI offshore yard for various clients around the world. Modern construction facilities and advanced technology enable HHI to provide any kind...

Open the catalog to page 12All HYUNDAI HEAVY INDUSTRIES catalogs and brochures

-

ENGINE & MACHINERY DIVISION

27 Pages

-

OFFSHORE & ENGINEERING

20 Pages

-

HHI SHIPBUILDING GROUP

25 Pages

-

Shipbuilding

42 Pages

-

Green Energy

8 Pages

-

Industrial Plant & Engineering

43 Pages

-

ELECTRO ELECTRIC SYSTEMS

40 Pages

-

Engine & Machinery

60 Pages

-

Engine 2012

52 Pages

Archived catalogs

-

ship building 2014

82 Pages

-

ship building 2013

82 Pages

-

Digital Brochure

34 Pages

-

Offshore

26 Pages