Website:

Dessalator

Website:

Dessalator

Catalog excerpts

USER’S MANUAL DESSALATOR® SOLO 60 LITRES / HOUR DESSALATOR® Technical and Sales Departments : Z.I des 3 Moulins – “Euro 92 – Bât. D – rue des Cistes – 06600 ANTIBES Tel: (33) (0)4 93 95 04 55 Fax: (33) (0)4 93 95 04 66 e-mail: dessalator@wanadoo.fr Web site: www.dessalator.com Version A1

Open the catalog to page 1

CONTENTS 1. Components page 1 2. How to install the desalinator: Sea water inlet page 2 Motor unit page 3 Membrane unit page 4 Control panel page 5 3. Starting the Dessalator® page 6 4. Directions for use (membranes) page 7 5. Maintenance: Cleaning the membranes page 8 Sterilizing the membranes page 9 High pressure pump page 9 6. Spare parts and accessories page 10 Appendix: A1: Reverse osmosis page 11 A2: How to assemble the HP connectors page 12 A3: Sterilizing cartridge – Instructions for use page 13 A4: Automatic rinsing page 14 A5: Troubleshooting page 15 Connection plan DES 12/24/230V...

Open the catalog to page 2

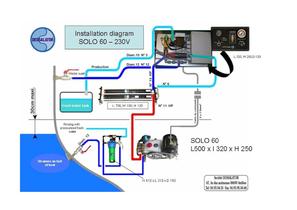

Installation diagram Socie» DESSAUTOR

Open the catalog to page 3

A B C SW 4 Pressure sensor high-pressure pump 0 - 100bar 4-20 mA Pressure sensor (Low pressure pump) 0 - 10 bar (OPTIONAL: 1 Rarely 2 fitted)) 3 1 2 3 - Rinse + Press. HP DES Press. BP 4 Water Production 4 - 20 mA 2003 01 LP J10 +22V 1 2 3 4 5 6 7 8 - CON8 Main 3-position Control Switch F1 5A J9 CON5 1 2 3 4 5 6 7 8 9 10 11 12 + + + + + J11 CON10AP 1 2 3 4 5 + + + + + J14 CON12 9 7 5 3 1 D? LED-Gn 3 3 2 1 10 8 6 4 2 OPTION J3 J4 J1 Relay J5 J2 J6 Relay V.24 serial port 230 V AC Input - Neutral Run on 230V AC J7 CON6 J13 CON3 D? LED-Y 24V Run on 12/24 V DC 3 D? LED-R +22V +22 V 1 2 3 4 5 6 +...

Open the catalog to page 4

1. Components supplied with the Dessalator®: Version A1 Hull valve: The hull valve strainer filters out the larger particles at system entrance. Pre-filter: The pre-filter filters out solid particles down to 5 µm at the motor unit inlet. It is supplied with wrench. For automatic rinsing an electro valve is mounted. Motor-Pump unit: The motor-pump unit is comprised of the 120, 230 or 400 V motor and a high pressure pump. It should be installed in a well-ventilated space. BEWARE: In 120V, please think of an even more important ventilation of the motor unit than in 230V. Membrane unit:: The...

Open the catalog to page 5

2. How to install the watermaker: 2.1 Sea water inlet Sea water inlet valve: The strainer should be positioned as low as possible below the waterline and as far as possible from the deck waste oulet. Drill the hull 21mm. The grooves on the strainer should be facing forward (towards the bow) for maximum water intake when the boat is moving forward. Please seal watertight with Rubson mastic or Sicaflex and ensure that the immersed part is painted with underwater grade paint. The hull valve should be accessible for maintenance. Make the valve / strainer and valve / hose connector watertight...

Open the catalog to page 6

2. How to install the desalinator: 2.2 Motor unit: The HP motor unit should be installed as low as possible in the boat in a horizontal position and it must be protected from water spray as much as possible. The unit is mounted using two alloy brackets under the two motors leaving a few centimetres clear space around the unit, to get sufficient air circulation space for motor cooling. The connection between 1 the prefilter oulet and the inlet to the low pressure side of the 2 pump is in Tricoflex hose of 12mm with doubled stainless jubilee clips at each joint. The HP head of the pump is...

Open the catalog to page 7

2. How to install the desalinator: 2.4 Membrane unit 1 The membranes can be installed either vertically or horizontally. 1 They are mounted using 4 Parker screws in alloy brackets . As 2 the hose from the HP pump vibrates, it is preferable to install the hose with an insulating tube. The HP connectors should be installed strictly in accordance with the instructions (Appendix A2). Apply a little loctite or nut seal to the two male and female cones before tightening. 2 3 Recommendation: To facilitate the connection , it is possible to rotate the heads through 90° by unscrewing the grey...

Open the catalog to page 8

2. How to install the desalinator: 2.5 Control panel: 1 6 2 3 5 7 8 1 4 2 The control panel must be mounted on a vertical surface as close as possible to the motor / pump unit and to the membranes. Leave space behind the panel to facilitate the connections. It is recommended that it is installed at the bottom or on the sides of cupboards, under chart table or main cabin seats, on the front panel of a rear bunk, … The panel has the following water connections: 1 HP pipe exiting the membranes (blue mark) 2 Production hose exiting the membranes (blue hose) 3 Production hose from panel to tanks...

Open the catalog to page 9

3. Starting the Dessalator : 1. Ensure the valves are open before starting up the desalinator (Hull valve and waste oulet valve if relevant) 2. If the desalinator has not been run for several days rinse with the three-way valve on the pre-filter as for normal rinsing before use. This should be carried out while the desalinator is idle and with the pressure regulator open (fully anti-clockwise). Rinse for two minutes. 3. To start the desalinator, the pressure regulator must be open. Switch on. 4. Turn the pressure regulator dial to the right, until the HP gauge reading is in the orange zone...

Open the catalog to page 10

4. Directions for use: MEMBRANES DELICATE COMPONENTS Reverse osmosis membranes must be carefully maintained as they are the most delicate elements of the reverse osmosis system. We recommend that the maintenance instructions are carefully followed to prevent the membranes from damage and to ensure the guarantee is not invalidated. Maximum production capacity of the desalinator is achieved with a sea water temperature of 25°C. The functioning of the membranes will vary depending on the temperature of the sea water. Output drops by approximately 2.5% to 5% for each degree below 25°C. Extreme...

Open the catalog to page 11

5. Maintenance: CAUTION: IN FREEZING CONDITIONS, PLEASE EMPTY THE FLOWMETER TUBE ON THE CONTROL PANEL BY DISCONNECTING THE PRODUCTION HOSE AND BLOWING OR INJECTING AIR INTO THE HOSE. 5.1. Maintaining the membranes 5.1.1 CLEANING THE MEMBRANES: When should the membranes be cleaned? After 800 working hours Under normal conditions, the membranes may be contaminated by mineral residues or biological matter. These residues reduce both the volume of drinking water produced and the amount of salt filtered out. The membranes should be cleaned whenever the volume of water produced is 10 to 15% lower...

Open the catalog to page 12All Dessalator catalogs and brochures

-

Commercial Brochure

24 Pages

-

DC Freedom 60

21 Pages

-

AC CRUISE 100

1 Pages

-

D90 PRO 230 or 400V

1 Pages

-

DC Freedom 30

22 Pages

-

AC CRUISE 60

1 Pages

-

Freedom 100

1 Pages

-

D2000 SPE

1 Pages

Archived catalogs

-

DUO 100

21 Pages

-

DUO 60

21 Pages

-

D 60

22 Pages

-

D 100

21 Pages

-

D440-D1000

16 Pages

-

D90 - D 280 REMOTE CONTROL

22 Pages

-

D 90 TO D 280

21 Pages

-

SOLO 100

19 Pages