Website:

Dessalator

Website:

Dessalator

Catalog excerpts

USER’S MANUAL INSTALLATION OF A DESSALATOR 440 TO 1,000 LITRES / HOUR IN 400 V BEWARE: DO NOT LIFT BY CHASSIS! DESSALATOR Technical and sales departments: Z.I des 3 Moulins – « Euro 92 » – Bât. D – rue des Cistes – 06600 ANTIBES Tel: (33) (0)4 93 95 04 55 Fax: (33) (0)4 93 95 04 66 Email: contact@dessalator.com Web Site: www.dessalator.com

Open the catalog to page 1

DESALINATOR 440 TO 1,000 LITRES / HOUR CONTENTS 1. Installation diagrams: Integrated control – Compact version page 1 2. Components supplied by DESSALATOR page 2 3. Installation instructions: 3.1 Pre pump 3.2 Membranes 3.3 Control panel 3.4 Motor unit 3.5 Connection plan page page page page page 4. Instructions for use page 8 5. Reverse osmosis principle 5.1. The membranes page 9 page 10 6. Maintenance: 6.1 Cleaning the membranes 6.2 Sterilizing the membranes page 11 page 12 3 4 5 6 7 7. Filters and power supply 7.1 Basket pre filter 7.2 Filter unit 7.3 Power supply on terminals page 13 8....

Open the catalog to page 2

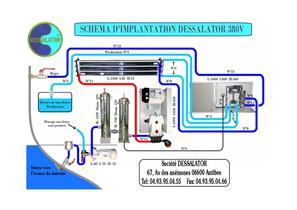

SCHEMA D'IMPLANTATION DESSALATOR 380V Stries vers Société DESSALATOR

Open the catalog to page 3

2. COMPONENTS SUPPLIED BY DESSALATOR ACCORDING TO THE CHOOSEN MODEL: Pre pump: It enables water to flow through the pre filters to the HP motor unit. Pre-filters: Stainless steel pre filter - multi cartridges 25 µm 10 Inch (x5): it allows a first filtration. It is supplied with an anode in its cover. Stainless steel pre filter - multi cartridges 5 µm 10 inch (x5): it allows a filtration up to 5µm; It is supplied with an anode in its cover. Motor unit: HP motor, fixed on a frame with silent blocks. Control panel HP motor unit Control panel: The control panel manages the functions of the...

Open the catalog to page 4

WATER MAKER - 440 TO 1,000 LITRES / HOUR 3.1 Installation instructions Pre pump: The pre pump with its rinsing valve3 and its pre filter should be installed in charge and the pressurized fresh water should be connected to the valve. Beware: Please check the rotating direction of the pre pump when starting up the machine. THE PRE PUMP SHOULD NOT BE PLACED WHERE THERE IS A RISK OF WATER SPRAY. Pre pump cable case 400V Pump cable case 400V LP Pump (three-phased motor 240 / 400) Beware: Check the direction of rotation HP pump (Motor 400 / 660V) Phase 1 Phase 1 Phase 2 Phase 2 Phase 3 Phase 3...

Open the catalog to page 5

WATER MAKER - 440 TO 1,000 LITRES / HOUR 3.2 Installation instructions Membrane(s), according to desired water flow: 2 membranes for 440 litres / hour water production. 3 membranes for 660 litres / hour water production. 4 membranes for 1000 litres / hour water production. The number of membranes used depends on the desired water flow. Le nombre de membranes est fonction du débit souhaité. Hose from the HP pump should join the membranes at the red ring1. 1 Recommendation: To facilitate the attachment to the HP stainless steel joins2, it is possible to rotate the heads through 90°, by...

Open the catalog to page 6

WATER MAKER - 440 TO 1,000 LITRES / HOUR 3.3 Installation instructions Panel pictures: 4 8 13 3 12 Beware: The handle is in the electric connection box (Security for shipment) Front panel Back panel 6 Figures for each connection are as follows: - N°8 (blue): HP piping exiting the membranes. - N°6 (blue hose 8/10mm diameter): Production hose exiting the membranes. - N°3: Production hose from panel to tanks. A 15mm inner diameter Tricoflex length will be required which should be connected either to the fresh water tanks or before the fresh water pump, provided there is no constricting valve....

Open the catalog to page 7

WATER MAKER - 440 TO 1,000 LITRES / HOUR 3.4 Installation instructions HP motor unit: There are two water connections to the pump head: - A ¾ diameter pipe1 from the pre filters. - A 19 mm diameter HP hose2 to the membranes. - Two capillary hoses are connected to the stainless steel pre filter; To disconnect them, please push the black collar and pull the hose at the same time. The HP unit should always be installed horizontally. Do not place it where there is a risk of water spray. The connection should be done as on the scheme below. 2 1 Page 6 . .

Open the catalog to page 8

WATER MAKER - 440 TO 1,000 LITRES / HOUR 4. Instructions for use 1. Ensure the valves are open before starting up the water maker. 2. If the water maker has not been run for several days, rinse it manually with the three-way valve on the pre-pump and start the pre pump. This should be carried out while the water maker is idle and with the pressure regulator open (fully anticlockwise).Rinse for two minutes. Purge in the same time stainless steel prefilters. 3. To start the water maker, the pressure regulator must be open. Switch on. The low pressure pump will run for one minute, after which...

Open the catalog to page 10

DESALINATOR 440 TO 1,000 LITRES / HOUR 5. REVERSE OSMOSIS PRINCIPLE What is the reverse osmosis principle used in your desalinating system? Sea water is forced at high pressure through the membranes which act as “molecular sieves”, only allowing pure fresh water to pass through. Most dissolved solid particles will not penetrate the membranes. This waste, along with remaining saline solution, will flow on the surface of the membranes and will be rejected. Not all particles dissolved in sea water can be eliminated. The system is designed to reject 99% of the TDS (Totally Dissolved Solids),...

Open the catalog to page 11

DESALINATOR 440 TO 1,000 LITRES / HOUR 5.1 THE MEMBRANES MEMBRANES, DELICATE COMPONENTS Reverse osmosis membranes must be carefully maintained as they are the most delicate elements of the reverse osmosis system. We recommend that the maintenance instructions are carefully followed to prevent the membranes from damage and to ensure the guarantee is not invalidated. Maximum production capacity of the water maker is achieved with sea water temperature of 25°C. The functioning of the membranes will vary depending on the temperature of the sea water and on the sailing area. Output drops by...

Open the catalog to page 12

DESALINATOR 440 TO 1,000 L/ HOUR 6.1 MAINTENANCE : Cleaning the membranes CAUTION: IN FREEZING CONDITIONS, EMPTY THE GAPMETER ON THE CONTROL PANELS, DISCONNECTING THE PRODUCTION PIPE AND BLOWING OR INJECTING AIR IN THE PIPE. CLEANING THE MEMBRANES: When should the membranes be cleaned? On average after 800 hours working. Under normal conditions, the membranes may be contaminated by mineral residues or biological matter. These residues reduce both the volume of drinking water produced and the amount of salt filtered out. The membranes should be cleaned whenever the volume of water produced...

Open the catalog to page 13All Dessalator catalogs and brochures

-

Commercial Brochure

24 Pages

-

DC Freedom 60

21 Pages

-

AC CRUISE 100

1 Pages

-

D90 PRO 230 or 400V

1 Pages

-

DC Freedom 30

22 Pages

-

AC CRUISE 60

1 Pages

-

Freedom 100

1 Pages

-

D2000 SPE

1 Pages

Archived catalogs

-

DUO 100

21 Pages

-

DUO 60

21 Pages

-

D 60

22 Pages

-

D 100

21 Pages

-

D90 - D 280 REMOTE CONTROL

22 Pages

-

D 90 TO D 280

21 Pages

-

SOLO 100

19 Pages

-

SOLO 60

19 Pages