Website:

African Cats

Website:

African Cats

Catalog excerpts

MULTI-SEASON ANTI-FOULING WORLDWIDE: WORLDCLASS + 10 YEARS LIFESPAN

Open the catalog to page 1

Coppercoat's development 2003 Hull all clean on 10th anniversary 2005 Coppercoat still performing after 12 years continual immersion public since 1991, COPPERCOAT is possibly the most powerful and long lasting anti-fouling available to the modern yachtsman. This hard wearing densely copper filled epoxy resin is successfully protecting tens of thousands of boats the world over, repeatedly saving their owners the time and expense of annual COPPERCOAT is the obvious choice for owners searching for increased performance with reduced costs from: First marketed under the brand name Copperbot by...

Open the catalog to page 2

COPPERCOAT is the combination of a specially developed solvent-free epoxy resin and high purity (99%) copper. Each litre of resin is impregnated with 2 kilograms of ultra fine spherical copper powder, the maximum allowed by law, making COPPERCOAT the strongest copper based anti-fouling available. Indeed no other anti-fouling exposes as much active copper to unwanted marine life as Classified as non-leaching, this highly effective coating is considerably kinder to the environment than its' self-eroding competitors whilst continuing to deter growth year after year. Indeed, correctly applied...

Open the catalog to page 3

40ft GRP commercial pilot vessel On immersion, sea water attacks the exposed pure copper powder, causing the formation of cuprous oxide. This highly effective anti-fouling agent deters growth until the surface degrades further to become cupric hydrochloride. This final copper form is highly unstable, and is washed away by the movement of the yacht, thereby removing any accumulating silt or slime. This automatically reveals a fresh copper rich surface, whereby the process recommences. With an average thickness of 250 microns of COPPERCOAT being applied in a treatment, and a typical corrosion...

Open the catalog to page 4

COPPERCOAT can be successfully applied to virtually all craft, irrespective of their size and usage, and is consequently sold to both the commercial and leisure sectors. While GRP vessels require no undercoat, boats constructed of wood, steel and ferro-cement can also be protected following the application Specifically designed to be user friendly, this solvent-free non-toxic coating should be mixed thoroughly, one unit at a time, and simply applied to the prepared surface by roller or spray. A complete treatment is usually achieved with four thin coats, applied "wet on tacky" in a...

Open the catalog to page 5

Then, depending on the vessel, apply a factor^ for full bodied craft, sud^sj^^Bbì^Jf'br1**'^ displac^Mijrt Bi^Kryachts, no factor is PPI^Hnor medium bodied craft, such as large fin and skeg or bilge keeled yachts, multiply by a factor of 0.75; while for light bodied craft, such as fin keeled yachts, multiply by a factor of 0.6. If the calculation is in feet, multiply the figure by 0.093 to convert to square metres. Given that COPPERCOM has an effective coverage rate of 4 square metres per litre for a full treatment of all the necessary coats, divide this figure by 4 to determine how many...

Open the catalog to page 6Archived catalogs

-

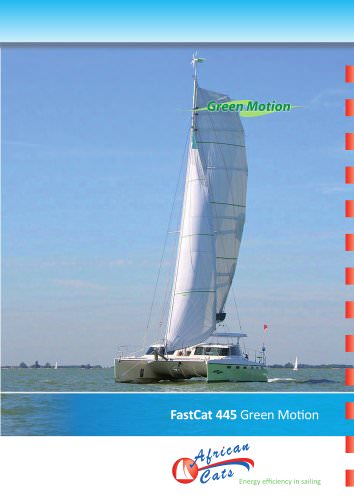

FASTCAT 445 Green Motion

4 Pages

-

Dyneema Webbing PR

1 Pages

-

PowerCat 420

9 Pages